When beginners get into laser engraving, they tend to concentrate on the equipment—laser power, work envelope, frame solidity, or air assist. All of these matter, but there's something else that silently makes or breaks every project: software. It's not merely software for getting designs into your machine, it's the underlying program controlling what level of detail, accuracy, and finished product quality you will end up with.

As a beginner, or if you're familiar, learning the proper use of software will most likely enhance the quality of engravings you get. This guide provides a step-by-step introduction to why software is so important, how to optimize settings, workflow tips, a comparison of popular options like TOOCAA Studio, LightBurn, and LaserGRBL, and how the TOOCAA L2 desktop laser engraver works with these software programs to achieve exceptional results.

Why Software Is Critical in Engraving Quality

Think of the engraving process as a team effort: your design, your software, and your machine all play different roles. If your design is sloppy, the best software in the world won’t save it. If your machine is unstable, even a perfect design and perfect settings may not come out right. But here’s the key: the software is the translator between design and hardware.

The laser itself doesn’t understand a picture of a logo or a photo of your dog. It only grasps power commands, movement speeds, and coordinates. It converts your image into programming commands known as G-code. It instructs the laser on where it needs to go, the intensity of the beam, and how long it will maintain the same position.

That's why two individuals operating the same machine can end up with drastically different outcomes. One may end up with crisp details, while the other burns through the material. The difference isn’t luck—it’s usually the software setup.

Here’s how the right software improves engraving quality:

Precision control – Adjusting laser speed and power at the micro level ensures your engraving doesn’t look washed out or scorched.

Path efficiency – Good software generates smarter movement paths, which reduces wasted time and gives smoother edges.

Consistency – Presets and saved settings mean you can repeat results on different projects or materials without endless trial and error.

Creativity unlock – Advanced features like photo dithering, multi-layer jobs, or curved text let you attempt designs that basic software simply can’t handle.

Without software, your machine is just a powerful light source. With software, it becomes a tool for creativity that can produce professional-quality results.

Adjusting Engraving Settings (Speed, Power)

Regardless of the software, there are three things most critical to the appearance of your project: speed, power, and layers. It is getting these correct which will give you good engraving.

Speed

Speed determines how quickly the laser head moves across the surface.

High speed → faster job times but lighter markings. Great for surface engraving where detail matters more than depth.

Low speed → deeper burns or cuts, but also more heat, which can scorch edges if not balanced with power.

A good rule of thumb is: engraving = higher speed, cutting = lower speed.

Power

Power controls how intense the laser beam is.

High power → deeper engravings and clean cuts, but risks burning.

Low power → softer marks that may not show up well on dark materials.

Some machines, like the TOOCAA L2, allow you to set different power levels for engraving vs cutting in the same job, which is a huge advantage.

Layers

Layers are where things get interesting. In software like TOOCAA Studio or LightBurn , you can assign different settings to each layer of a design:

Engraving layer → high speed, medium power for surface detail.

Cutting layer → lower speed, higher power for cutting shapes.

Marking layer → very low power for faint lines (like guides or alignment marks).

By stacking layers, you can engrave a logo, cut out the coaster shape, and add alignment marks in a single run.

Practical Tip: Use Test Grids

One of the smartest things beginners can do is create test grids. These are small squares engraved at different speed and power combinations on your material. After one test run, you’ll know exactly which settings work best without guessing. Save these results in your software as presets, and you’ll never have to start from scratch again.

Workflow Tips: From Design to Final Product

Even if your settings are perfect, poor workflow can waste time and materials. Here are proven tips for building an efficient, frustration-free process:

Start with the right file type – Vector files (SVG, AI, DXF) are always better for engraving and cutting. Raster images (JPG, PNG) work for photos, but they don’t scale well.

Plan your canvas size – Match the software’s canvas to your material dimensions before you start designing. Nothing is worse than realizing your design is too big after pressing “Start.”

Use color coding for layers – Assign colors to different parts of your design to easily separate engraving, cutting, and marking steps.

Check alignment with framing – Most software offers a “frame” or “outline” preview that moves the laser around the edges of your design. Always do this to confirm placement.

Preview paths – Use the simulation preview to catch mistakes before they waste material. This is especially important for complex jobs with multiple layers.

Work in steps – For large or expensive projects, consider running a test on scrap material first. Small investments in testing save big losses later.

Organize presets by material – Over time, build a library of presets for common materials like birch plywood, slate, acrylic, or leather. This turns hours of trial and error into one-click consistency.

When you follow a clear workflow, engraving feels less like a gamble and more like a repeatable, professional process.

Comparing Different Software (Ease of Use, Precision)

Choosing software has got to be mind-boggling, so we will look at the most common desktop engraving options:

LightBurn

Pros: It has professional features, easy-to-use design tools, simple layer management, and it supports many different file types.

Better For: Enthusiasts seeking advanced features or small business use with a priority on efficiency.

Why We Like It: Its preview and path optimization capabilities help with time and material savings. It also works very well with equipment like the TOOCAA L2.

LaserGRBL

Pros: It's cost-free, lightweight, and simple. Suitable for beginners.

Cons: There are limited tools for design—you generally need to create designs elsewhere first (such as Inkscape).

Best For: Beginners or amateurs who are not willing to invest money right away.

TOOCAA Studio

Pros: Tailored software developed exclusively for the TOOCAA L2 with simple installation and trouble-free configuration. Ideal beginners with no-fuss settings and native compatibility.

Cons: The software currently lacks LightBurn's level of adaptability with high-end drawing software and customization, but this functionality is on the product roadmap for future development.

Best For: First-time customers looking for a quick solution that works instantly with their T device.

Why It Stands Out: TOOCAA Studio goes smoothly with the hardware immediately, as opposed to other software. It therefore minimizes error and simplifies the initial engraving process considerably.

Free software substitutes (Inkscape + plugins, etc.)

Pros: It's free, adaptable, and has.

Cons: Installation can prove challenging, and assistance choices are limited.

Best For: People who like to tinker and experiment.

If you are looking for something easy to use instantly, TOOCAA Studio is the way you should go. If you are trying out engraving and you don't need to add extra funds, LaserGRBL should do. And if you require extra features and more control altogether, LightBurn still has the highest standing.

Case Study: TOOCAA L2 with LightBurn for High-Quality Results

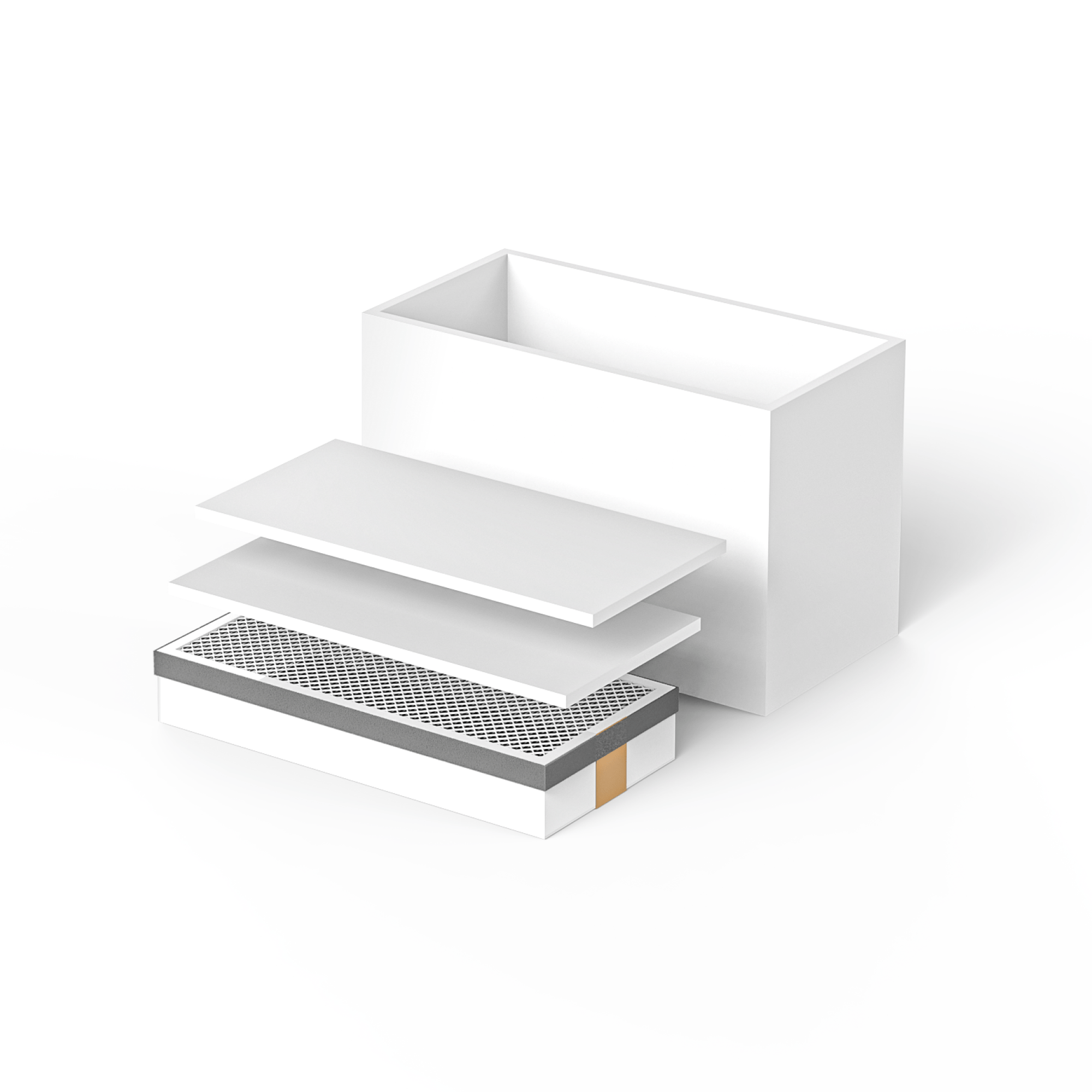

The TOOCAA L2 Desktop Laser Engraver & Cutter is a great example of how hardware and software complement each other.

Machine Highlights

Laser heads: 10W or 20W options for flexibility.

Work area: 400 × 415 mm—large enough for signs, trays, or coasters, but compact enough for a workbench.

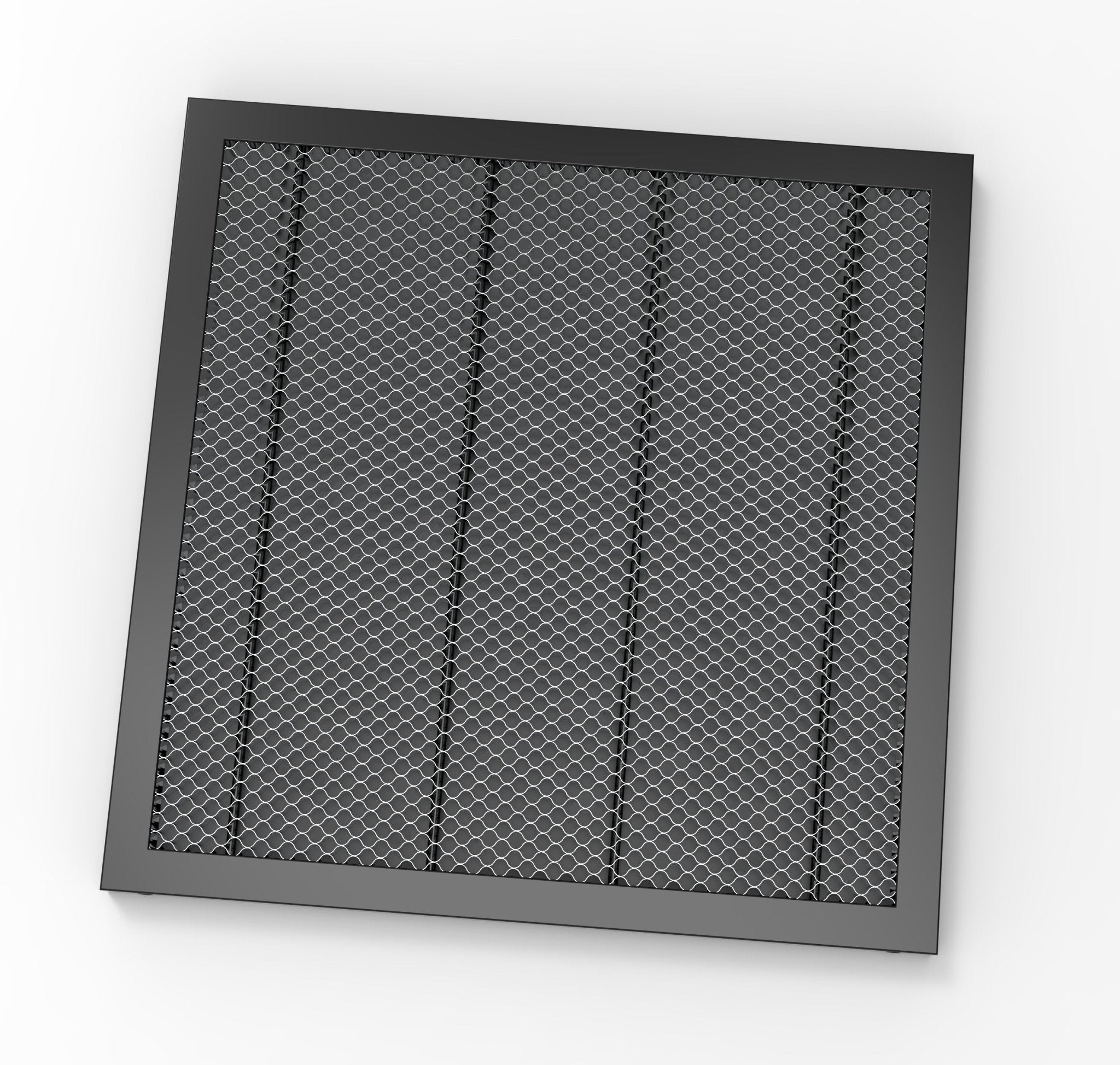

Material compatibility: Cuts and engraves wood, leather, acrylic, rubber, paper, and coated metals.

With LaserGRBL

Beginners can quickly load a design, set basic speed and power, and start engraving. It’s straightforward and perfect for learning.

With TOOCAA Studio

This software is tailored specifically for the TOOCAA L2, offering simple installation and hassle-free configuration. It provides native compatibility and no-fuss settings, making it ideal for first-time users looking for a quick solution that works instantly with their device .

With LightBurn

This is where the machine truly shines. Using LightBurn, you can:

Assign multiple layers for engraving + cutting in one project.

Save material presets (like “birch ply 3mm cut” or “slate photo engrave”).

Preview jobs in detail before pressing “Start.”

Optimize paths to save engraving time on larger projects.

For example, engraving a set of custom wooden coasters becomes simple:

Import the logo (SVG file).

Assign a light engraving layer for the logo details.

Assign a cutting layer for the coaster shape.

Run a preview, adjust placement, and press start.

The result? Professional-grade coasters, consistent every time.

Conclusion: Software + TOOCAA L2 = Professional Outcomes

At the end of the day, a laser engraver only performs its job perfectly if the software is proper. With the proper tool, process, and adjustment, you will advance from beginner tests to finished products earlier than you think.

The TOOCAA L2 has a great mix of features: strong hardware, a big work area, and it works with both easy software (TOOCAA Studio and LaserGRBL ) and more advanced software (LightBurn). If you set it up correctly and use a smooth process, your engravings will look professional, even if you are new to it.

If you want reliable, good quality outputs, you have to use the TOOCAA L2 from TOOCAA with the correct engraving software. It’s the most effective upgrade you can make without changing your hardware.