Story

Laser engraving machines as we know them are only used in some large factories and workplaces, and cannot be used in underground warehouses or houses. When infectious diseases become serious around the world, people have no opportunity to be active and spend their time at home. Therefore, all kinds of sophisticated small gifts, furniture, accessories, etc. were produced.

Of course, the tools used to create these things are often sold. Therefore, a low-power version of the laser engraving machine suitable for home use has been developed.

Laser Engraving Type

There are three main types of laser engraving machines.

CO2 laser engraving machine: Uses a carbon dioxide beam to penetrate the material. However, the efficiency is low. Therefore, it is ideal for engraving and cutting non-metallic materials such as paper, cloth, leather, and wood.

Diode laser engraving machine: increasingly popular among hobbyists and manufacturers. The diode of this laser is generally an optoelectronic device that converts electrical energy into light to produce high-intensity coherent light that is used to engrave objects.

Fiber laser engraving machine: produces a powerful laser beam by pumping highly intense light through a fiber optic cable. These cables are generally doped with ytterbium and emit high-capacity energy in the form of photons.

How does a laser engraving machine work?

Laser engraving produces a focused laser beam and transmits it into the material. When used correctly, the laser leaves a permanent mark on materials extremely resistant to wear. The laser generation and delivery method varies depending on the specific laser technology, but it is passed through a lens for focusing.

What happens when the laser touches the material depends on the user's goals. The laser generates enormous amounts of heat at specific locations on the material, vaporizing or simply burning the material to the point where visible contrast is created.

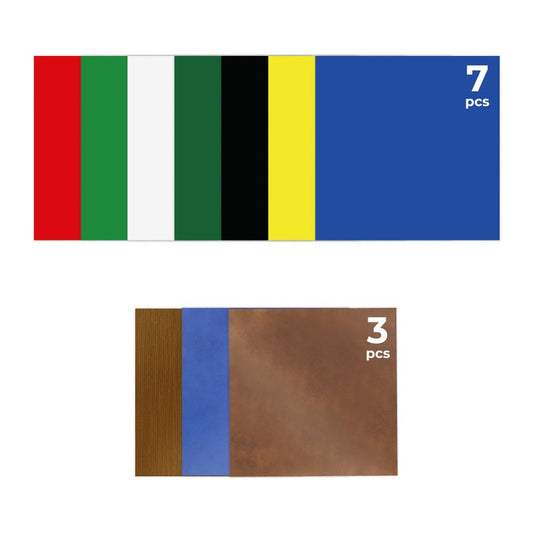

Materials for laser engraving

The more compatible the materials, the easier it is for the laser engraving machine to be used in a variety of applications. Projects allow you to be more creative and explore different materials.

The best laser engraving machines are compatible with a variety of materials such as wood, leather, paper, cartons, and glass. Generally, the stronger the laser engraving machine, the more material it can engrave and cut. Therefore, it is important to check the hardware compatibility of your laser engraver before purchasing.

Common materials used for laser engraving include:

1.Glass: One of the best materials for laser engraving. Laser manipulation can be performed on all glasses to obtain an aesthetic effect. It can be a wine glass, bottle, vase or cup.

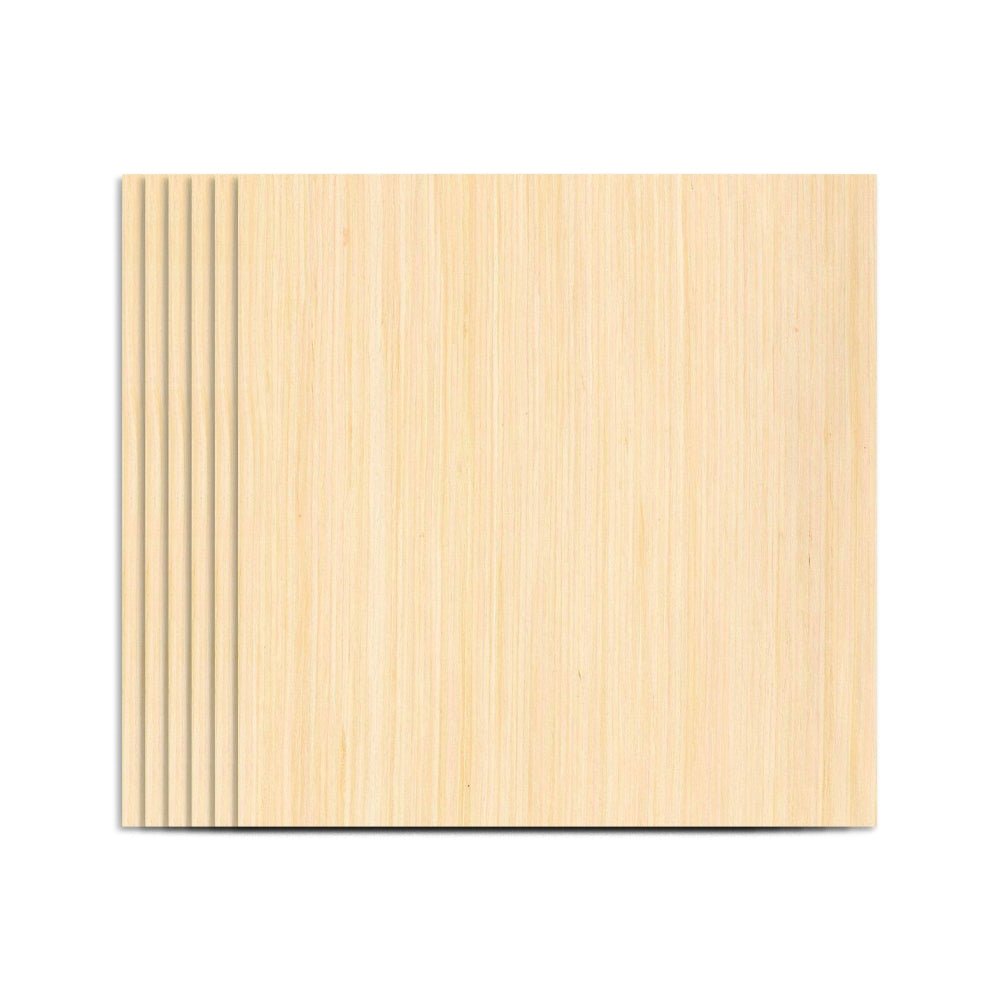

2. Wood: It is a popular carving material that is cheap and easily available. You can also use all types of wood for laser engraving and cutting with different results. The most commonly used wood types for carving are plywood, MDF, hardwood, natural wood, particleboard, HDF, and veneer.

3. Marble and granite: Marble and granite are mainly used for photo engravings because they provide a very good contrast with the engravings. Use dark materials for a better aesthetic.

4. Brick and Stone: Ideal for carving objects exposed to different weather conditions. Therefore, it is ideal for sculptural parts used for monuments and outdoor patios.

5.Leather: Like fabric, this material can also be personalized through engraving. Carved leather is in high demand, and the most commonly carved materials are natural leather, suede, artificial leather, suede, and Alcantara leather.

6. Metals: All types of metals can be engraved, but the most common metals are stainless steel, iron, steel, brass, aluminum, and silver.

7. Acrylic: A durable, reliable, and lightweight alternative to glass.

Laser Engraving Software

Good software allows you to take full advantage of the hardware capabilities of your laser engraver. Both design and motion control software are important in any laser engraving software suite. Lightburn, LaserGRB, and Inkscape are some of the well-known and feature-rich options available for laser engraving.

Lightburn

Control and editing software package. Lightburn is used to obtain various bitmap and vector graphics image formats. This software allows you to edit and configure vector graphics as well as create new graphics. When used with a laser engraving machine, it is very efficient as files can be sent directly to the machine.

Features:

1. Works with a variety of popular image formats and vector graphics, including AI. DXF, SVG, GIF, PNG, PLT.

2. Base applications were created for Linux, Windows, and Mac OS.

3. Create, configure, and edit new vector shapes in the editor.

4. Some powerful features such as welding, node editing, offset, Boolean operations, etc.

5. It has multipath, speed, power, dithering mode, cutting order, brightness and contrast.

LaserGRBL

Free laser engraving software designed for DIY laser engraving. Regarded as the most popular Windows GCode streamer, this software can be used to upload or stream images, pictures, and GCode passes for burning logos. Specially designed for amateur laser engravers and cutters, its unique properties have been further enhanced.

Features:

1.Custom button support

2. Ideal for image fragments using vectorization, dithering, and grayscale conversion.

3. GRBL configuration for import and export

4.Provides real-time projection and order preview

5. Provides various color scheme adjustment functions for use with different glasses

6. Home button, resume button, power hold button, GRBL reset button function

Inkscape

It is a free and open source software that is widely considered the most effective alternative to Adobe Illustrator. The fact that laser engraving machines are constantly evolving and improving the user experience confirms their popularity.

Features:

1. The default format is SVG (Scalable Vector Graphics).

2. Provides a markup language that is a royalty-free means of graphical formalization. time. You can create your own designs using H. commands.

3. Works equally seamlessly on all operating system platforms including Windows, Linux, and Mac OS.

4. It has clone, pen tool, shape tool, and text tool to create objects.

5. Facilitate object manipulation through object grouping, task and layer variations, raising and lowering, and command reordering and deployment.

6. Fill and outline using pattern fills, path indicators, color selectors, dotted strokes, and more.

7. Provides text support such as shape text, multiline text, path text, and character spacing.

Difference between laser engraver and laser cutter

Laser cutting machines and laser engraving machines are almost the same machines. The biggest difference is the laser performance and the materials it can work with.

Laser engraving machines have a weak laser that is only used for engraving. However, it is possible to modify a laser engraving machine to function as a laser cutting machine. If the speed is too low and the laser intensity is too high, it will cut wood, paper, and some plastics.

Laser cutting machines, on the other hand, have much more powerful lasers to engrave and cut materials. Of course, a laser cutting machine costs more than an engraver. CO2 lasers and fiber lasers are expensive and require more advanced technology to operate.

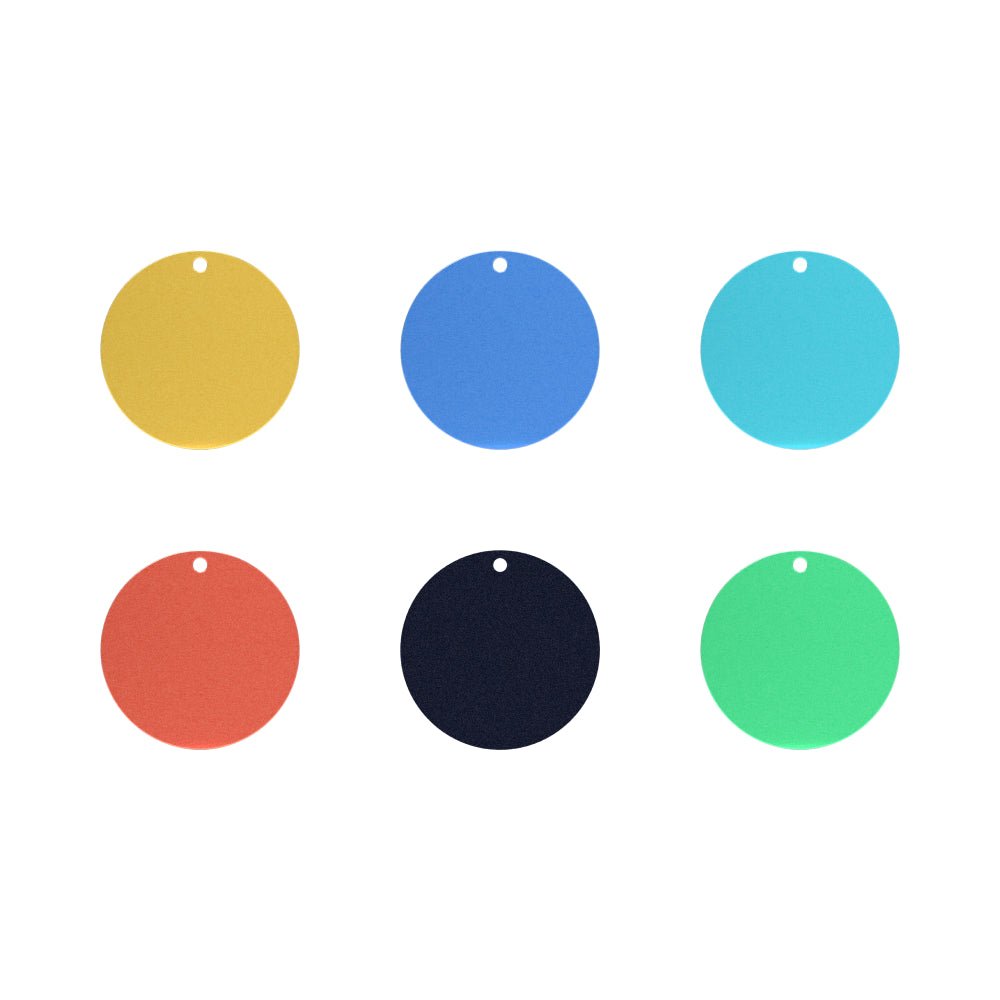

If your main purpose is to personalize die-cut items or engrave keychains, bookmarks, or simple models, a laser engraver is a good choice. Laser cutting machines are the ideal choice when you need to cut customized designs and want full laser cutting and engraving capabilities.

How to choose laser engraving

Most laser machines you can buy online can engrave, but not all laser engravers can cut.

Low-power diode lasers are preferred for engraving soft materials such as paperboard, paper, and cloth. Nowadays, higher-power diodes are also becoming increasingly common, and manufacturers are incorporating multiple diode lasers into one tool head to achieve higher output intensities than traditional diode laser engraving machines. looking at These new tool heads can provide similar output intensities to CO2 lasers, but are much more expensive and cannot be purchased in large quantities.

There are generally plenty of low-power diode lasers and cheaper open-frame devices that cost between $200 and $500. Ideal for soft materials, paper, cloth, etc. Although the effect is not as good as the CO2 laser cutting machine, at least the CO2 laser cutting machine is much more expensive than these diode laser engraving machines.

Ultimately, the efficiency and ease of use of laser engraving largely depend on the software. LightBurn is often considered one of the best software on the market. Many brands on the market have developed their own laser engraving software, but most are in beta versions. Very complex images may not be engraved or cut smoothly. In contrast, there are many laser engraving machines that are fully compatible with LightBurn.

To help you make your choice, we tested different brands of laser engraving machines to narrow down the different options. Whether you are looking for a reasonably priced laser engraving machine or a machine that meets your specific material or application requirements. Personally, I think the TOOCAA L1 laser engraving machine can meet all your needs.

TOOCAA L1 Laser Engraver

TOOCAA L1 laser engraving machine is one of the most cost-effective laser engraving products on the market. The assembly steps are very simple and can be assembled directly.

Light in weight, and easy to carry, you can work anytime and anywhere.

TOOCAA L1 laser engraving machine is compared with other brands of laser engraving machines. The whole body is made of anodized aluminum alloy, an L-shaped silicone foot, and an 8mm steel rail to ensure accurate and smooth movement of the laser head during work.

The protective film of the laser head is FDA safety level 1 and can filter 90% of UV rays, allowing users to use the machine without wearing security lights. The fan with a carbon filter can effectively absorb smoke and dust, protect the user's respiratory tract, ensure the quality of stamped products, and prevent the work surface from becoming black.

This laser engraving machine supports Windows/Mac OS computers and TF cards, providing users with various options. Supports common file formats such as SVG, DXF, JPG, JPEG, PNG, BMP, etc. It also works with many of the most popular software applications on the market, such as LightBurn, LaserGRBL, etc.

Also, the brand offers a very strong WIKI library with diverse and interesting cases of the brand. You can access the WIKI library and download patterns at any time. They hire professional designers to regularly expand their database, and users can upload and share their projects with the community.

How to use a laser engraving machine?

Preparation

First, make sure the material fits your laser engraving work area and trim if necessary. We will also carry out test cutting and engraving operations and prepare to import spare equipment.

Laser engraving jobs don't necessarily require additional tools, but in my experience the following tools are helpful:

1. All-purpose knife: Used for cutting materials that are not perfectly cut by the laser cutter, or for trimming paper and cards.

2. Painting Tape/Adhesive Tape: Used to tape the surface of the material to prevent stretching and to tape light materials.

3. Windup/Caliper: Used to measure dimensions and ensure the final object is the correct size.

Setting

The four most important parameters of a laser-cutting machine are power, speed, frequency, and focal length.

1. Power: Displays the laser output power. Usually adjustable from 0 to 100% (maximum output). Use high power to cut thicker materials and lower power to cut thinner materials such as paper.

2. Speed: Determines the speed at which the laser head moves. When engraving and cutting thin materials, the speed is usually set to (almost) maximum.

3. Frequency (Hz, PPI): The frequency parameter indicates the number of laser pulses per second. The frequency depends entirely on the materials used. For example, woodblock prints work best at around 500-1,000Hz, and acrylics recommend 5,000-20,000Hz on the soft end.

4. Focusing: As already mentioned, the laser head has a focusing lens. For most applications, the focal point (where the laser beam is thinnest) must be above or slightly below the surface of the material. To ensure this, the material must be at a certain distance from the lens. The exact distance depends on the type of focus lens you use.

believe me. You now have the tools you need. Each laser cutter has a different working process. I know the TOOCAA L1 laser engraver from ELECFREAKS. Next, let's talk about the basic operation using TOOCA L1 as an example.

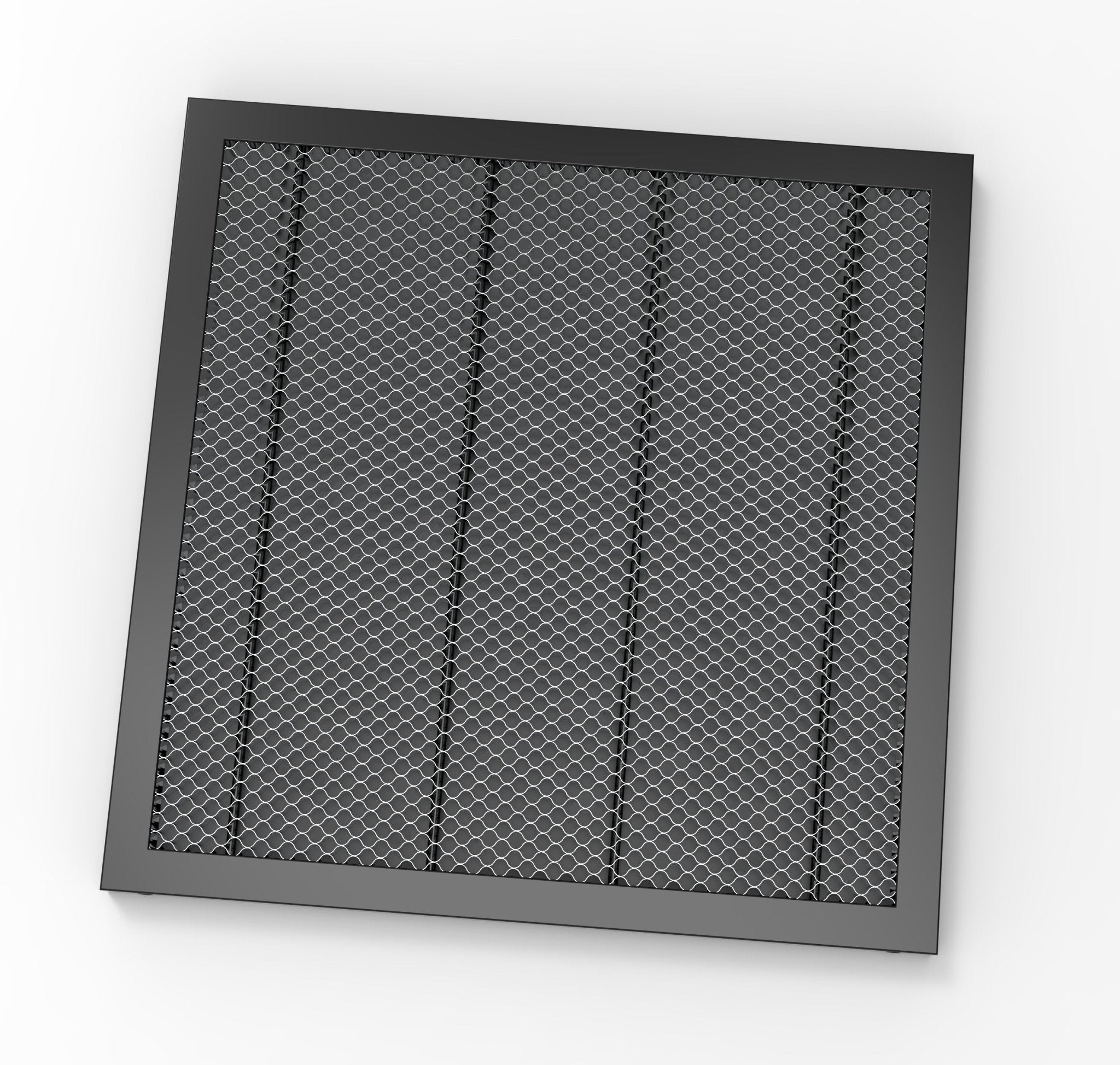

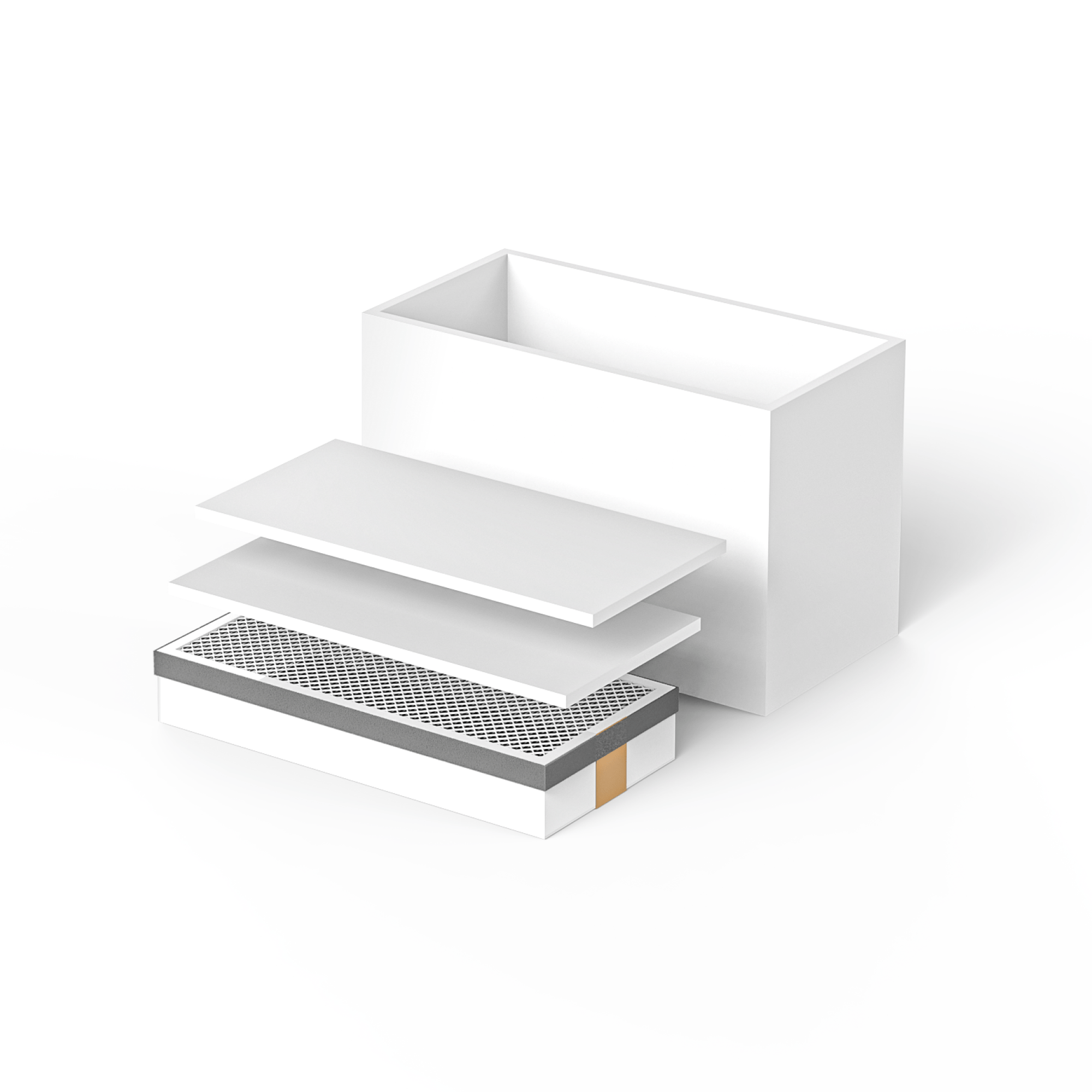

The first step is to place the laser cutter on a large work platform, such as the floor or table. Place the material you want to engrave or cut out in your work area. (Note: I personally recommend placing a honeycomb plate under the material. This will prevent the laser beam from damaging the floor or work platform when cutting or engraving.)

The second step is to position the material to be engraved or cut and focus it using the focusing aid that comes with the laser cutting machine.

In the third step, turn on the laser cutter and connect your laptop to the USB cable. (Note: Some laser cutting machines also support offline jobs or SD card jobs.)

The fourth step is to import the pattern you want to engrave or cut into the software you want to use. I usually use LaserGRBL and it's easy to use.

The fifth step is to set the laser head movement speed and frequency in LaserGRBL. (Note: Please set the parameters according to the material you want to engrave or cut.)

Finally, click get to work. After a while, you will receive the case you want.

Precautions when using a laser engraving machine

Using laser engraving machines is extremely dangerous and harmful to your health. Before using the laser engraving machine, the following protective work must be carried out.

laser beam protection

Lasers can cause serious eye damage. For safety reasons, consider wearing a laser security mirror. When choosing these protective tools, you should consider the glasses that directly match the type of laser engraving you want to use.

This is easy, as information about the laser can be found in the instruction manual. This includes information such as optimal density and wavelength range. Wear laser glasses during the engraving process and remove them only when the device is no longer in use.

Smoke

Laser-cutting machines easily produce fumes, particles, metal fumes, and smoke from the substrate that are highly toxic. It is important to wear personal protective equipment when using a laser-cutting machine. Additionally, stores selling these tools must have a well-equipped filtration system.

Extractors are ideal for these workplaces as they remove dangerous fumes from the air and protect against exposure to heavy metals and toxic particles.

Possible side effects caused by laser smoke exposure include:

Metal steam heat:

This usually occurs due to zinc fumes released when cutting certain steel alloys. Common symptoms of zinc smoke include pain, cough attacks, flu, and fever.

Annoying things:

Contact with chemicals can irritate eyes, skin, mouth, and noise.

Accumulation of toxic chemicals:

Over time, toxic fumes accumulate in the body and cause unwanted chemical reactions. This can eventually lead to lead poisoning and kidney problems.

Exposure to carcinogenic compounds is common, especially when hexavalent chromium is present. Dangerous particles that can cause cancer. According to numerous research studies, this unpleasant particle can quickly cause several side effects, including Examples: skin wounds, and nose, mouth, and eye irritation.

Ventilation

Laser machines, especially those using CO2, generally emit dangerous fumes, so these devices require ventilation. Therefore, do not forget to work in a well-ventilated room. Modern laser engraving systems are equipped with exhaust systems to protect the air inside the laser cutting machine and around the laser, but be sure to open doors and windows to facilitate air circulation.

Conclusion

You'll be amazed at the variety of laser engraving options available on the market! Be sure to consider what you will be using it for before purchasing. However, finding the best laser engraver is easy if you know exactly what you're looking for and how you want to use the equipment for your craft.

Every engraving enthusiast wants a laser engraving machine but for different reasons. Requirements vary depending on materials, type of design, purpose of the project, etc. We hope our guide and advice will help you make the right choice for your first laser-cutting machine!