Laser engraving and cutting are total game-changers for businesses and hobbyists alike. Whether you are creating personalized gifts, amazing decorations, or running a small business, with a laser machine, you can engrave complex designs onto wood, acrylic, leather, and even metal. More and more individuals are picking up laser engraving and converting their imaginative concepts into beautiful, one-of-a-kind masterpieces.

But let's get real here—lasers aren't toys. They're serious business. We're talking about heat, fire hazards, noxious fumes, and powerful laser beams that can injure you if you're not careful. In this tutorial here, we're going to walk you through all you need to know to be safe, from basic precautions to more advanced safety techniques.

Industrial vs. Hobbyist Laser Use: What's the Difference?

Before jumping in, one should appreciate that not every laser system is equal. Professional equipment and DIY stations have primary differences that impact safety precautions.

Industrial lasers: These work-house machines (most often CO₂ or fiber lasers) are used in manufacturing, metal cutting, and mass production. They need special ventilation, rigorous maintenance, and adherence to professional safety procedures. Operators typically receive special training to use these machines safely and efficiently.

Hobbyist lasers: Miniature CO₂ or diode lasers, ideal for home projects, small-scale enterprises, or custom designs. They are cheaper and more accessible but require safe handling and appropriate precautions. Home users tend to have their workshops in garage or home craft rooms, so air circulation and fire control are crucial.

As you go through this guide, we will indicate which of the safety tips are for industrial or home use so you can adapt them to your workspace.

Familiarization with the Hazards of Laser Cutting & Engraving

Physical Hazards

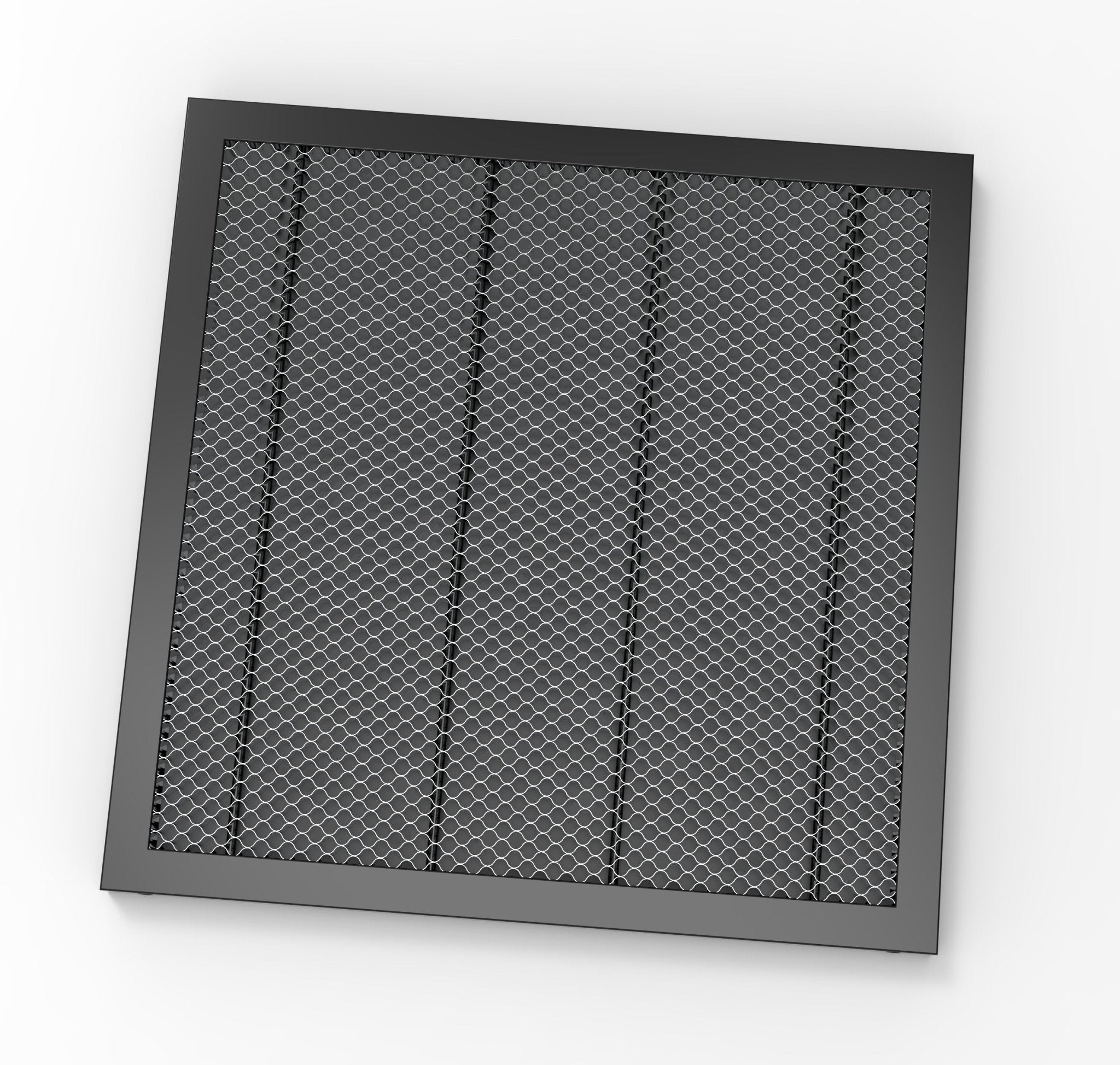

Laser beams are harmful at low power, too. Air beams or reflective beams have the potential to ruin your eyes forever, so always wear eye protection. Glossy surfaces such as metal enhance the chances of beams reflecting in an unwanted manner, so precautions are even more important. Enclosures come with most laser systems to minimize this likelihood, but special care still needs to be exercised.

When carrying out projects, brittle material like glass or certain types of plastic, tiny pointed chips can spall off and cut your skin or eyes. Safety glasses, gloves, and a bit of good protective gear are helpful there. And don't forget—freshly-cut edges can be extremely sharp, so handle them with care unless something's in your future.

Chemical Hazards

Some materials give off toxic fumes when they are cut or etched. For example:

MDF (medium-density fiberboard) emits formaldehyde, which irritates the lungs and causes chronic disease on prolonged exposure.

PVC (polyvinyl chloride) off-gasses chlorine gas, which is highly toxic, corrosive, and will destroy your laser machine permanently.

Cherry wood is reportedly known to emit cyanide compounds when burned, requiring ventilation to avoid dangerous exposure.

Always research materials before cutting and ensure your workspace is properly ventilated. If in doubt, check manufacturer guidelines or material safety data sheets (MSDS) to determine whether a material can be used with a laser.

Psychological Hazards

Operating a laser machine for hours on end leads to fatigue and decision burnout. Before you know it, errors creep in—like leaving an operating laser unattended or using the wrong settings. The mental load of managing orders, machine maintenance, and design concepts can also lead to stress and neglect.

To avoid this, break regularly, set reminders to review projects, and develop habits that ensure safety. A clear mind is a safe mind.

Ventilation & Air Filtration: Making the Air Safe

Proper ventilation is essential, always and everywhere, virtually regardless of the size of the room you work in. Some of the common filtration techniques are:

HEPA filters: Catch fine dust particles but must be replaced frequently. Ideal for workshops with minimal or no fumes.

Carbon filters: Capture fumes and odors but not solid particles. Perform best when used in conjunction with other forms of filtration.

Industrial cyclones: Best for heavy duty cleaning but worst for very small fumes. Less commonly found in houses.

For home installations, a basic exhaust fan in conjunction with a carbon filtering system can dramatically enhance air quality. If operating indoors, look for a fume extractor for laser use and have fresh airflow circulating at all times to minimize harmful exposure.

Safe Equipment Use & Workspace Setup

A well-organized workspace is safer. Here's how to maximize yours:

Create a "golden triangle" working setup (laser, computer, controls) for productivity and reduced travel, with immediate access to key tools.

Inspection of wiring should be carried out regularly in order to prevent electrical fires. Loose or frayed cables need to be replaced immediately.

Make a fire extinguisher readily accessible when working on wood, acrylic, or other flammable materials. A CO₂ extinguisher is best suited for laser-involved fires.

Never let the laser operate by itself—blazes start within seconds. Install timers or use remote monitoring wherever possible.

With industrial use, have proper marking, emergency outlets, and daily safety exercises. When working many machines, consider having a safety officer monitor actions.

I would like to recommend this video to everyone. It discusses how to handle fires encountered during use, emphasizes the importance of avoiding unattended situations and using fire extinguishers, and suggests using spray bottles and airflow assistance to prevent fires.

Laser Safety Devices & Protective Apparel

To lower risks, seek out these security features:

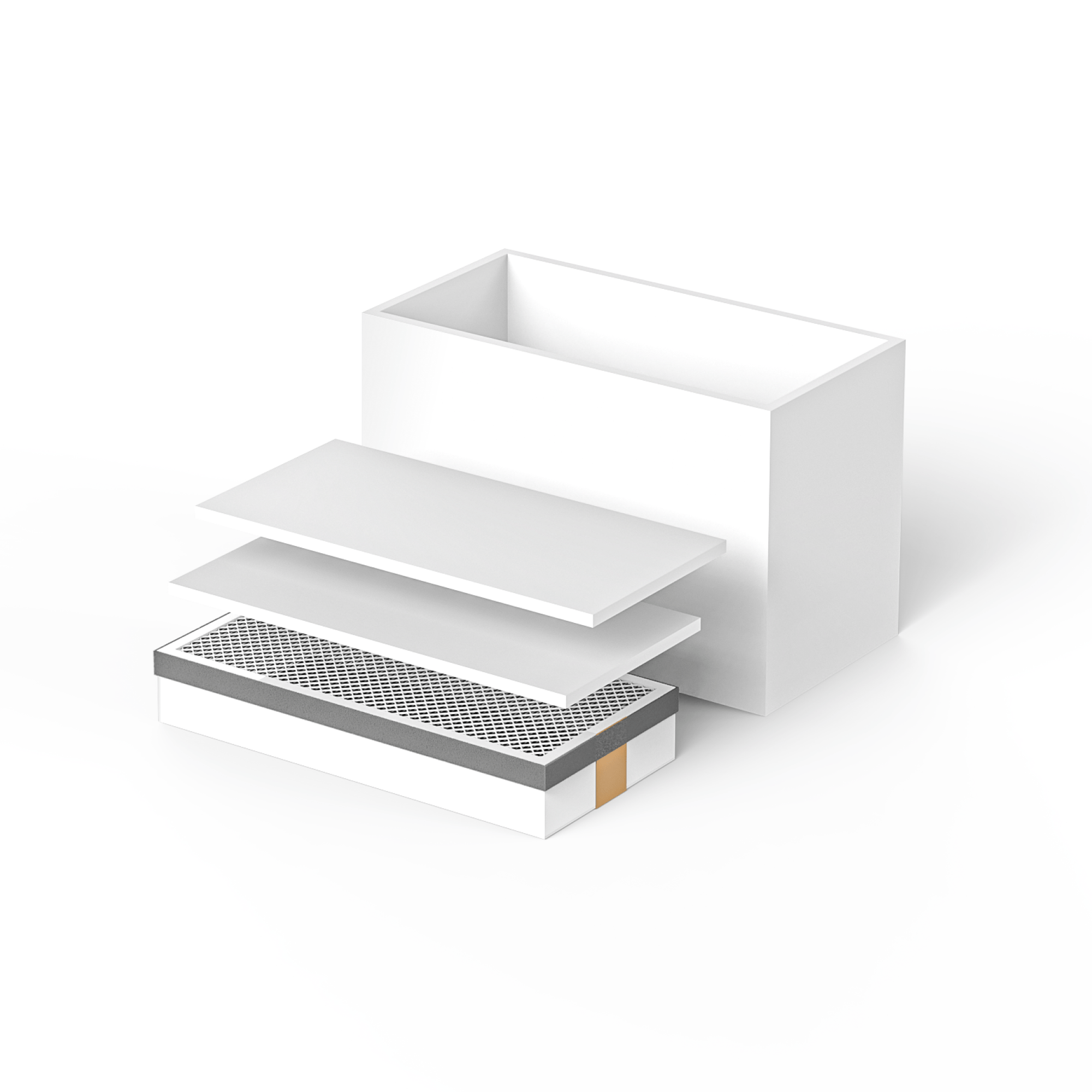

Shields and covers for protection: Prevents direct exposure of the laser beam and reduces chance of reflections.

Emergency stop button: Shuts off the laser instantly in case of an emergency, preventing further damage or injury.

Automatic shutoff: New lasers will shut down if the enclosure is left open, another safety measure.

Smoke and fire detectors: Disasters prevented early. Smart sensors will detect unusual smoke behavior and shut down operations automatically.

Personal protective equipment (PPE): Laser safety goggles tailored to your laser's wavelength. Heat-resistant gloves for handling materials that retain heat after cutting.

Respirators when handling potentially dangerous fumes, especially in enclosures.

Future of Laser Safety: Smarter Tech & AI Monitoring

There are emerging technologies in laser technology that are making machines safer. Some of the technologies include:

AI-based monitoring that detects anomalies and shuts down the laser if needed, preventing potential accidents.

Water mist or CO₂ gas-powered automatic fire suppression systems, especially in industrial environments.

Intelligent ventilation systems responding to cutting material, optimizing real-time air quality.

As this technology becomes standard, laser cutting will be safer for both professionals and hobbyists.

Fine Tuning Laser Settings for Safety & Efficiency

Getting the settings precise is the trick to safe and effective laser use:

Power & speed: Increased power = deeper cuts, but too much will char the material. Adjust settings to material thickness and type.

Frequency: Lower frequencies optimum for cutting; higher frequencies for improved engraving detail and less charring of material.

Test before committing: Test cuts always performed on scrap material to determine the best settings.

For commercial users, parameter optimization can reduce errors and improve consistency between lots of production.

Conclusion: Laser Safety as a Mindset

Safety with lasers isn't a matter of regulation, though—it's a matter of developing good habits. Right or wrong, you're in an environment either at home in a workshop or commercial setting, and by taking the proper precautions, you can partake in your hobby without unnecessary hazard.

Make safety routine: check out ventilation, wear protective gear, monitor your equipment, and never cut corners. With the right attitude, you can continue creating amazing things without endangering yourself and others.

So go for it—activate that laser, but do so safely!