Best Sellers

Creator Spotlight: See How the Pros Create

We put Toocaa in the hands of the most creative minds. See how they push the limits and get inspired for your next masterpiece.

Why Shop With TOOCAA

We Inspire Every Dreamer, Every Field

STEM Education

Small Business

Small Business

DIY

Our Influencer

News & Blogs

Laser engraving and cutting are total game-changers for businesses and hobbyists alike. Whether you are creating personalized gifts, amazing decorations, or running a small business, with a laser machine, you can engrave complex designs onto wood, acrylic, leather, and even metal. More and more individuals are picking up laser engraving and converting their imaginative concepts into beautiful, one-of-a-kind masterpieces.

But let's get real here—lasers aren't toys. They're serious business. We're talking about heat, fire hazards, noxious fumes, and powerful laser beams that can injure you if you're not careful. In this tutorial here, we're going to walk you through all you need to know to be safe, from basic precautions to more advanced safety techniques.

Industrial vs. Hobbyist Laser Use: What's the Difference?

Before jumping in, one should appreciate that not every laser system is equal. Professional equipment and DIY stations have primary differences that impact safety precautions.

Industrial lasers: These work-house machines (most often CO₂ or fiber lasers) are used in manufacturing, metal cutting, and mass production. They need special ventilation, rigorous maintenance, and adherence to professional safety procedures. Operators typically receive special training to use these machines safely and efficiently.

Hobbyist lasers: Miniature CO₂ or diode lasers, ideal for home projects, small-scale enterprises, or custom designs. They are cheaper and more accessible but require safe handling and appropriate precautions. Home users tend to have their workshops in garage or home craft rooms, so air circulation and fire control are crucial.

As you go through this guide, we will indicate which of the safety tips are for industrial or home use so you can adapt them to your workspace.

Familiarization with the Hazards of Laser Cutting & Engraving

Physical Hazards

Laser beams are harmful at low power, too. Air beams or reflective beams have the potential to ruin your eyes forever, so always wear eye protection. Glossy surfaces such as metal enhance the chances of beams reflecting in an unwanted manner, so precautions are even more important. Enclosures come with most laser systems to minimize this likelihood, but special care still needs to be exercised.

When carrying out projects, brittle material like glass or certain types of plastic, tiny pointed chips can spall off and cut your skin or eyes. Safety glasses, gloves, and a bit of good protective gear are helpful there. And don't forget—freshly-cut edges can be extremely sharp, so handle them with care unless something's in your future.

Chemical Hazards

Some materials give off toxic fumes when they are cut or etched. For example:

MDF (medium-density fiberboard) emits formaldehyde, which irritates the lungs and causes chronic disease on prolonged exposure.

PVC (polyvinyl chloride) off-gasses chlorine gas, which is highly toxic, corrosive, and will destroy your laser machine permanently.

Cherry wood is reportedly known to emit cyanide compounds when burned, requiring ventilation to avoid dangerous exposure.

Always research materials before cutting and ensure your workspace is properly ventilated. If in doubt, check manufacturer guidelines or material safety data sheets (MSDS) to determine whether a material can be used with a laser.

Psychological Hazards

Operating a laser machine for hours on end leads to fatigue and decision burnout. Before you know it, errors creep in—like leaving an operating laser unattended or using the wrong settings. The mental load of managing orders, machine maintenance, and design concepts can also lead to stress and neglect.

To avoid this, break regularly, set reminders to review projects, and develop habits that ensure safety. A clear mind is a safe mind.

Ventilation & Air Filtration: Making the Air Safe

Proper ventilation is essential, always and everywhere, virtually regardless of the size of the room you work in. Some of the common filtration techniques are:

HEPA filters: Catch fine dust particles but must be replaced frequently. Ideal for workshops with minimal or no fumes.

Carbon filters: Capture fumes and odors but not solid particles. Perform best when used in conjunction with other forms of filtration.

Industrial cyclones: Best for heavy duty cleaning but worst for very small fumes. Less commonly found in houses.

For home installations, a basic exhaust fan in conjunction with a carbon filtering system can dramatically enhance air quality. If operating indoors, look for a fume extractor for laser use and have fresh airflow circulating at all times to minimize harmful exposure.

Safe Equipment Use & Workspace Setup

A well-organized workspace is safer. Here's how to maximize yours:

Create a "golden triangle" working setup (laser, computer, controls) for productivity and reduced travel, with immediate access to key tools.

Inspection of wiring should be carried out regularly in order to prevent electrical fires. Loose or frayed cables need to be replaced immediately.

Make a fire extinguisher readily accessible when working on wood, acrylic, or other flammable materials. A CO₂ extinguisher is best suited for laser-involved fires.

Never let the laser operate by itself—blazes start within seconds. Install timers or use remote monitoring wherever possible.

With industrial use, have proper marking, emergency outlets, and daily safety exercises. When working many machines, consider having a safety officer monitor actions.

I would like to recommend this video to everyone. It discusses how to handle fires encountered during use, emphasizes the importance of avoiding unattended situations and using fire extinguishers, and suggests using spray bottles and airflow assistance to prevent fires.

Laser Safety Devices & Protective Apparel

To lower risks, seek out these security features:

Shields and covers for protection: Prevents direct exposure of the laser beam and reduces chance of reflections.

Emergency stop button: Shuts off the laser instantly in case of an emergency, preventing further damage or injury.

Automatic shutoff: New lasers will shut down if the enclosure is left open, another safety measure.

Smoke and fire detectors: Disasters prevented early. Smart sensors will detect unusual smoke behavior and shut down operations automatically.

Personal protective equipment (PPE): Laser safety goggles tailored to your laser's wavelength. Heat-resistant gloves for handling materials that retain heat after cutting.

Respirators when handling potentially dangerous fumes, especially in enclosures.

Future of Laser Safety: Smarter Tech & AI Monitoring

There are emerging technologies in laser technology that are making machines safer. Some of the technologies include:

AI-based monitoring that detects anomalies and shuts down the laser if needed, preventing potential accidents.

Water mist or CO₂ gas-powered automatic fire suppression systems, especially in industrial environments.

Intelligent ventilation systems responding to cutting material, optimizing real-time air quality.

As this technology becomes standard, laser cutting will be safer for both professionals and hobbyists.

Fine Tuning Laser Settings for Safety & Efficiency

Getting the settings precise is the trick to safe and effective laser use:

Power & speed: Increased power = deeper cuts, but too much will char the material. Adjust settings to material thickness and type.

Frequency: Lower frequencies optimum for cutting; higher frequencies for improved engraving detail and less charring of material.

Test before committing: Test cuts always performed on scrap material to determine the best settings.

For commercial users, parameter optimization can reduce errors and improve consistency between lots of production.

Conclusion: Laser Safety as a Mindset

Safety with lasers isn't a matter of regulation, though—it's a matter of developing good habits. Right or wrong, you're in an environment either at home in a workshop or commercial setting, and by taking the proper precautions, you can partake in your hobby without unnecessary hazard.

Make safety routine: check out ventilation, wear protective gear, monitor your equipment, and never cut corners. With the right attitude, you can continue creating amazing things without endangering yourself and others.

So go for it—activate that laser, but do so safely!

Laser cutting and engraving have various industrial uses, as well as being a popular hobby at the same time. Diode lasers stand out as the go-to tools of choice for at-home hobbyists and enthusiasts due to their compact size, versatility and affordable pricing. They are suitable for popular surfaces like wood, but the question is, does that include softer materials like leather?

The short answer is yes; however, there are certain things to keep in mind, including securing optimal conditions for the procedure, choosing the right device, and avoiding certain health risks. But let’s not get ahead of ourselves - you can read all about these in today’s post where I’ll share everything you need to know, even as a complete beginner.

Understanding laser cutting and engraving

Laser cutting and engraving are delicate processes that require a fair amount of precision, even on flat and hardened surfaces. Therefore, introducing additional challenges in the form of unstable surfaces (such as in the case of leather) can potentially complicate the equation.

The reason being is that the procedure heavily relies on laser beams to vaporize or etch materials. To cut or engrave leather, we need to make sure that the material gets heated enough for this to be made possible, allowing for clean cuts and detailed engravings to be made.

Types of lasers that are suitable for leather surfaces

As far as leather engraving goes, there are two recommended options at your disposal:

CO2 lasers

Among their advantages are versatility, a high power output, and the fact that, besides leather, they can handle a wide range of materials. On top of that, they are suitable for large-scale operations, effectively allowing you to potentially turn your passion into an industrial level business. High precision and speed tend to be their defining attributes. Their power can often exceed 50W.

Diode lasers

Compared to CO2 lasers, diode lasers are much smaller in comparison and they tend to pack a lighter punch (anything from 5W to 40W). However, they are on the affordable end of the spectrum; that, combined with their compact dimensions, makes them more than fitting for at-home use. Under the right conditions, they are suitable for working with leather.

Keep in mind that engraving leather generally requires less power than cutting it, which makes diode lasers the perfect tools for the job. Set them correctly, and they can even tackle curved leather surfaces with utmost precision. Based on my experience, CO2 lasers are the preferred choice for factory owners and similar, while diode lasers lead the way as far as setting up a small business or enjoying a hobby goes.

Are diode lasers suitable for cutting or engraving leather?

Yes, but there are certain limitations to keep in mind. In other words, we need to ensure the following suitable conditions:

- Power requirements. Lower-power models typically range from 5W-10W and this may not be sufficient to effectively cut through thicker leather. Aim for higher-power diode lasers in the range of 20W-40W, as these are generally suitable even for cutting through thicker leather surfaces. From my personal experience, 20W tends to be the sweet spot for working with leather materials of all shapes, sizes, and makings.

- Speed and precision. To ensure a higher level of precision and ensure clean cuts, we need to slow down the process accordingly. However, the extra consistency is well worth the tradeoff of the process taking longer to complete.

- Material compatibility. Not all types of leather are suitable for the purpose. Generally speaking, full-grain and top-grain leathers tend to work best. Avoid synthetic types of leather such as PVC as it can emit toxic fumes. Instead, consider going with vegetable-tanned leather due to its organic composition.

Pro tip: TOOCAA L2 Desktop Laser Engraver & Cutter is available in several different power variants: 10W, 20W and 40W. You can further customize your order bundle by picking the exact add-ons you require. This can be the Air Assist, Smoke Purifier, Additional Materials, Rotary Roller and more. It comes in 8 layers of safety, which includes a flame detector, a smoke exhaust system, a lid-open detector and more. Give it a try - it’s extremely user-friendly!

Best practices for cutting and engraving leather

For optimal results when working with leather, it’s recommended to follow the best industry practices.

1. Select the correct materials. We recommend full-grain or top-grain leather as these tend to be the easiest to work with.

2. Choose the correct power and speed settings on your engraving laser. Adjust them based on the thickness of the leather that you’re working with. Generally speaking, opting for lower speed ensures a higher degree of precision.

3. Equip your device with air assist (to pick up debris). This will ensure that excess debris gets out of the way and that you will experience zero burn marks in the process. Speaking of which, adjusting the laser focus settings also goes a long way towards preventing these and so does cleaning the surface before you begin.

4. Ensure proper safety measures. If you’re working with potentially toxic materials, ventilation is key.

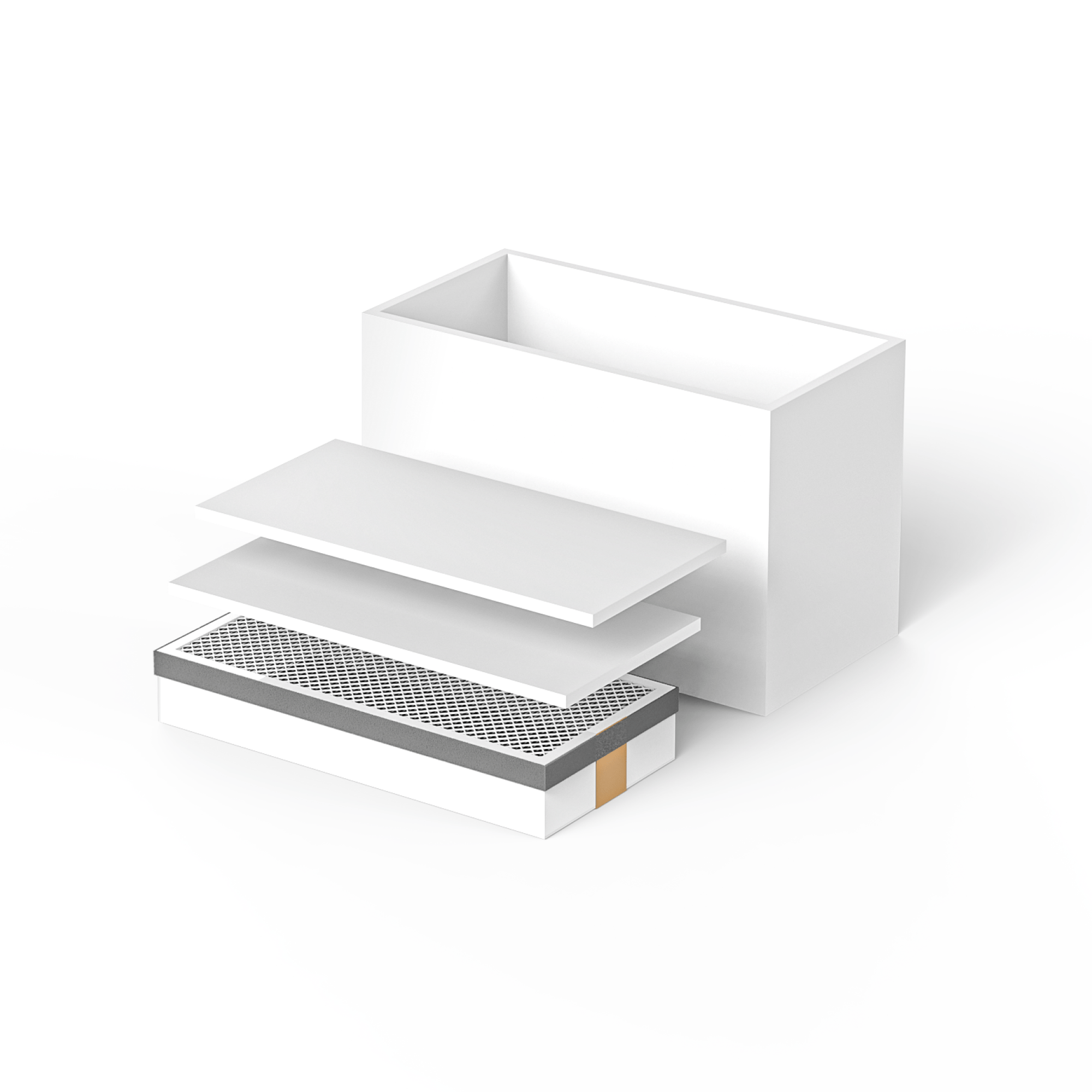

Pro tip: Thanks to its 3-stage filtration system, TOOCAA smoke purifier will make sure that no toxic emissions remain in the room after using your laser engraving machine. It’s quiet and extremely easy to install. In fact, it has a proven capacity of being able to filter out 99.7% of um particles, thus creating a safe and family-friendly environment where your creativity can thrive.

Advantages of using diode lasers for cutting leather

The great thing about picking diode lasers as your tool of choice is that you get to utilize their several key advantages:

- Affordability. Putting them side-by-side with their CO2 alternatives, diode lasers come out on top as the budget-friendlier option. This makes them the preferred choice among hobbyists and DIY enthusiasts.

- Compact design. Irrespective of the space you have available in your workshop or at home, chances are you’ll be able to fit one of these in without making excessive adjustments. This makes diode lasers a suitable choice for condos and small living spaces.

- Versatility. Apart from being able to cut or engrave leather, investing in a diode laser also gives you the right tool you need to work with several other materials, including wood, fabric, acrylic and more.

Does engraving or cutting leather with a desktop diode laser have any limitations?

Depending on all the variables that go into the equation (the type of leather, your device and the rest we’ve discussed), there are certain risks and limitations involved:

- Carbonization. Choose the wrong settings for the job, and burn marks can occur on the edges of the cut leather. Typically, this tends to be an issue with higher power settings.

- Certain diode laser brands may not provide the cut quality you’re looking for when compared to CO2 alternatives.

- Efficiency. Generally speaking, diode lasers typically take longer to complete the job simply due to having a lower power density. However, this is only a limitation in the context of mass-scale operations.

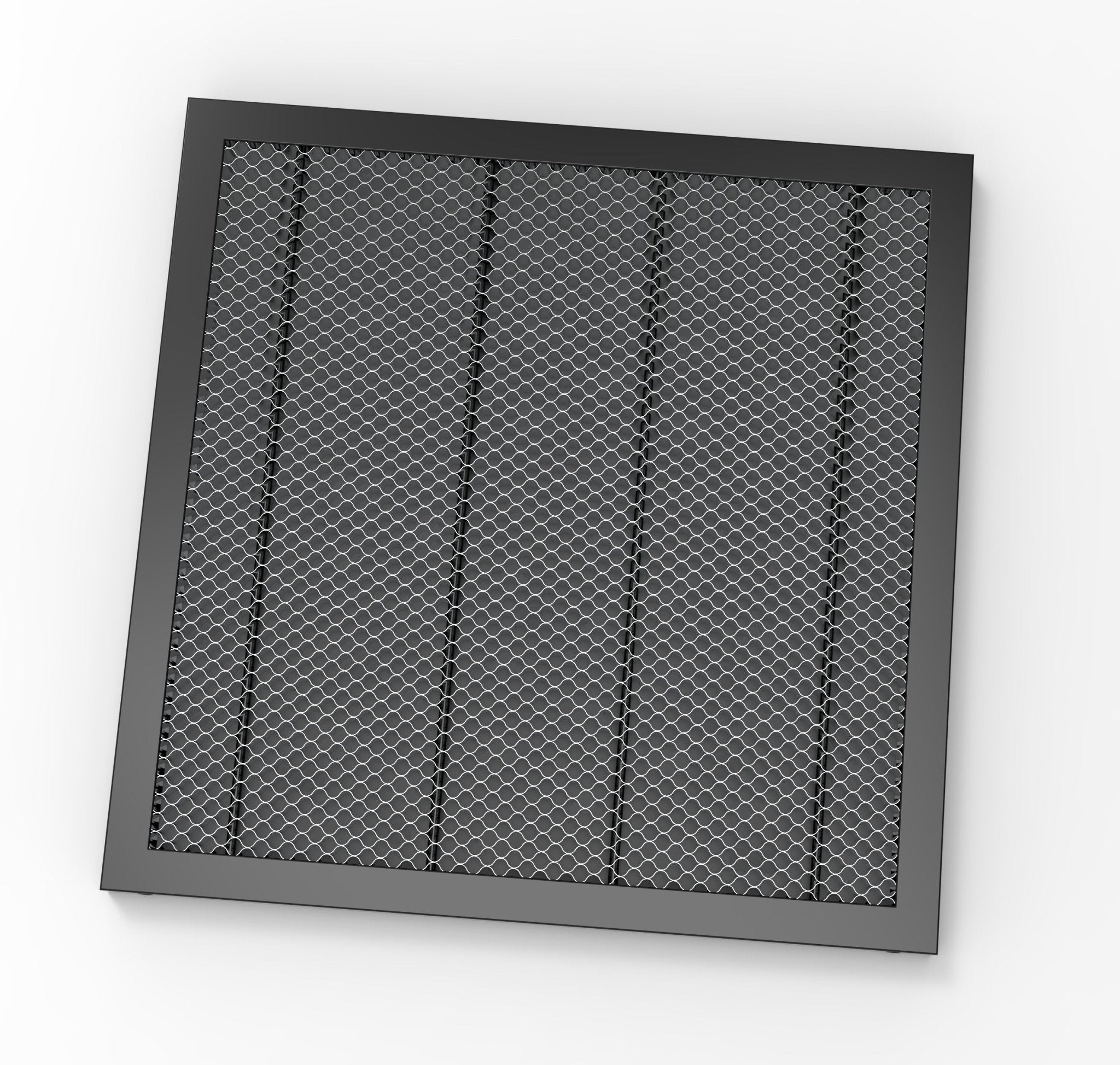

I wanna also introduce a video to you, which maybe very useful for beginners I think! The video introduces how to use a diode laser cutter to cut leather, including methods for fixing the leather with a honeycomb bed, preventing edge burning, and cleaning the laser lens to ensure cutting effectiveness. Moistening the leather can reduce smoke damage and improve cutting quality, while using magnets and popsicle sticks helps secure thinner leather.

Practical use case ideas for laser-cut leather designs

Wondering what you could do with your newfound passion? Below, you will find a couple of inspiring ideas on what kind of creativity can come about when cutting or engraving leather:

- Making fashion accessories aesthetically pleasing. Imagine having leather wallets, bags, and belts with your own custom engraved designs on them. A real head-turner!

- Adding a personal touch to your items. Have you ever felt that your leather items are too generic? Make them stand out with custom engravings and you’ll immediately recognize which one is yours, even from a distance.

- Give the perfect gift. Know someone who enjoys customized works of art? Surprise them with a thoughtful gift made of leather. This could be a custom bracelet, or perhaps a necklace with a leather pendant.

- Decorate your existing clothing and make it even more fashionable. You’d be surprised how much of a refreshed look a leather patch can give to an old hat for example.

- Industrial uses and rapid prototyping. Have an idea that you’d like to quickly put into action? Whether it be belts, bags, shoes or other customized products and fashion essentials, having a laser engraving machine at hand can get you from point A to point B quickly and efficiently.

- Make customized steering wheel wraps. Are you a car-owner? Make your vehicle’s interior stand out by infusing it with customized leather designs.

- Give your home decor a refresh. Wouldn’t it be nice to have lampshades, furniture accents, or perhaps even wall art made out of custom-cut leather? Imagine the wonders this could do for your motivation and general well-being, simply by living in a space that’s designed to inspire.

Conclusion

By knowing how to approach the task correctly, using a diode laser to cut or engrave leather can be done with more than satisfying results. Thanks to their compact dimensions and general affordability, these devices tend to be the favorite among hobbyists and small-scale users.

Just make sure to dial in the correct power settings, pick the right kind of leather to work with, and ensure the proper safety measures, and your diode laser is bound to serve you well, whether you’re planning to use it for a small art project or even to start a small business.

While you’re at it, don’t forget to give our TOOCAA product catalog a look!

Why do most industries prefer laser-cutting machines over traditional means? Simple! It's because of their ease of use, efficiency, precision, and time-saving powers.

Hence, laser-cutting machines have practical applications in many industries. In the 21st century, a sector that doesn't utilize these machines hardly exists.

But in what applications is a laser cutting machine used?

Depending on the type, a laser cutting machine is always dedicated to cutting different materials, such as metal, wood, fabric, glass, plastic, or polymer, and an industry can use it for different purposes.

This article explores the applications of laser-cutting machines in various industries.

What is Laser Cutting?

Laser cutting uses laser, a large beam of light generated by a laser source, to cut and engrave materials. It is an effective cutting method since it is 100% precise, leaving no margin of error.

Most industries are turning to this amazing technology not only for its precise cutting and shaping ability but also because it prevents material waste.

With a growing population, there's a need for daily equipment production, and you will agree when we recommend laser cutting machines to minimize production wastage.

However, it is important to note that laser cutting is categorized into three:

Remote Cutting

Remote cutting is used when working with thin materials because of their weight. This process partially removes metals and excludes the cutting gases (CO2, helium, and nitrogen).

Flame Cutting

The materials are subjected to acetylene or natural gas to melt their surfaces.

Fusion Cutting

Argon and other inert gases serve as cutting gases used to melt materials. Inert gases prevent chemical reactions with atmospheric oxygen, so the metal's surface may not be subjected to further treatment.

Check out this Toocaa L2 laser engraver cutter.

Industrial Applications of Laser Cutting

Automobile Industry

Laser-cutting machines are a blessing to the automobile industry. Over the past few years, there has been an increased production of complex, high-end automobiles. Also, in the automobile industry, there is no room for error; therefore, there's a need to ensure accuracy and precision in manufacturing materials.

Laser-cutting machines reduce the need for additional finishing touches or extra machining. This ensures the standards required in automobile manufacturing are being maintained. Examples of parts that are produced include:

· Body panels

· Engine bracket

· Chassis components

· Trunk lids

· Door frames

· Fuel tanks

· Windshield

· Roof panels

· Motor mount

· Brackets

Windshields and every product are made of high-tensile steel and aluminum.

Aerospace Industry

Laser cutting machines are more advantageous than traditional cutting methods in aerospace. They are faster, more precise, and safer for humans. They can be used to cut a variety of materials at varying thickness. This makes them an essential tool in the aerospace industry.

Laser-cutting machines are used in the manufacture of aircraft and spacecraft parts such as:

· Engine casings

· Turbine blades

· Fasteners

· Panel assemblies

· Wing structures

· Exhaust cones

· Fuel tank components

· Locking mechanisms

· Heat shields

· Gaskets

Laser-cutting machines are created with top-tier technology that helps minimize material waste. It reduces the rate of thermal distortion and preserves the integrity of aircraft and shift craft materials.

We believe that these machines will forever be valued in the aerospace industry. This is primarily due to the need to produce more aircraft to cater human wants and needs. Another is to produce aircraft that are lightweight following the regulatory safety standards.

Medical Industry

Laser-cutting machines deserve high praise for producing high-quality medical equipment, complex designs, and patterns that traditional means cannot achieve successfully. Precision and accuracy are two terms held dearly in the medical world because of how delicate human life is.

For example, pacemakers, implants, hip replacements, knee replacements, and spinal implants are always customized to fit the patient's body and for proper functionality.

Another benefit of laser-cutting machines is their ability to produce more parts in bulk at a fast rate. This is a huge blessing in the medical field because of the high demand for this equipment.

Other examples of tools that are produced by laser technology are:

· Dental implants

· Stents

· Surgical instruments

· Spinal implants

· Catheters

· Gaskets

· Endoscopic tools

· Knee replacements

Electrical Industry

Laser-cutting machines are a breath of fresh air in the electrical industry as they are used in making electrical boards, circuit boards, connectors, and other equipment used in homes and businesses.

For example, with laser technology, you can drill holes as tiny as 0.03 to 0.05 mm. This is important because as technology advances, we must discard obsolete and cumbersome ways of making heavy and complex devices.

We should stick to smaller and much more intricate types. All laser cutting machines cut with 100% accuracy with less than 0.01% margin of error.

Fitness Equipment

Laser-cutting machines are relatively new to the manufacture of gym and fitness equipment compared to other industries. Nonetheless, there are benefits to using laser cutting machines over traditional cutters.

They are time-saving and durable. Finally, they are more environmentally friendly, as the conventional method creates more unhealthy waste and fumes for us and the environment.

Pipe Processing

The pipe processing industry is one of the many beneficiaries of laser cutters. They can cut all types of pipes into various diameters and shapes regardless of thickness. Laser cutters are more creative than traditional methods, which are restricted to certain cuts and patterns.

Agricultural Industry

The agriculture industry extensively uses laser cutting machines for cutting and molding of metals. Examples include aluminum, titanium, iron, stainless steel, and other so on. Laser cutters are much faster than traditional methods, such as water jet cutting.

They have the power to cut over 10 times thicknesses than what a water jet cutter does. Laser cutters produce clean and sharp edges, a feat traditional methods cannot achieve. This means less time post-processing and sharpening the edges.

Finally, agricultural equipment produced with laser-cutting machines can withstand harsh and unfavorable weather conditions.

Furniture Industry

The hallmark of the furniture business is creativity and the ability to think outside the box. As a furniture maker, create creative designs with a laser cutter as your cutting and engraving tool.

This means you can customize logos, designs, motifs, and drawings. Explore your creative mind, or bring your client's creative thoughts to light.

Compared to the traditional method of cutting and engraving, this is preferred because it is easy to use, requires less manual labor, and gives the best quality.

Kitchenware Industry

Laser-cutting machines are used to cut and engrave kitchenware. We all love personally customized and designed kitchen utensils, which can be made of glass, stainless steel, ceramic, or aluminum.

Customized kitchenware can also be given as gifts to your loved ones. It is a great flex to have customized kitchenware as it always makes it easy to identify.

Steel Industry

Laser-cutting machines are used to cut steel because of their high speed, precision, and accuracy. Steel can be cut into various plates, sizes, and shapes depending on the desired use. In addition to its cutting prowess, it can be used to weld two or more steel materials together.

Common Laser Cutting Materials

Before you invest in a laser cutting machine, you want to know if the technology works with your materials. Here are the common materials you can cut with a laser cutter:

Carbon Steel

Carbon steel is the combination of steel and varying concentrations of carbon, ranging from 0.12% to 2%. Carbon has a high melting point, so the higher the percentage of carbon present, the higher the melting point and the easier it is cut.

A fiber laser is the most preferred method for this type of material. The speed is solely dependent on the thickness of the material. The smaller the thickness, the faster the speed.

Copper

Fiber lasers are advisable for cutting copper, as they prevent copper discoloration. However, in the absence of fiber laser cutters, CO2 laser cutters can be used. Remember to spray the material with metals with the same wavelength as CO2 laser cutting machines.

Titanium

Titanium is strong and has a high melting point. Though challenging, it is possible to cut with the right settings. For the best results, use a CO2 laser in conjunction with oxygen or nitrogen. Laser-cut titanium is widely used because of its strength and lightweight nature.

Plastics

Another material that laser-cutting machines can handle is plastics. The best type for cutting is CO2, while diode is excellent for engraving. Some examples of plastics lasers can cut include acrylic styrene and polyoxymethylene.

Metals

Metal can be cut with either CO2 or diode laser cutters. Metals are the most common because they are used in virtually every industry for stop Examples include aluminum, brass, carbon steel, copper, and stainless steel.

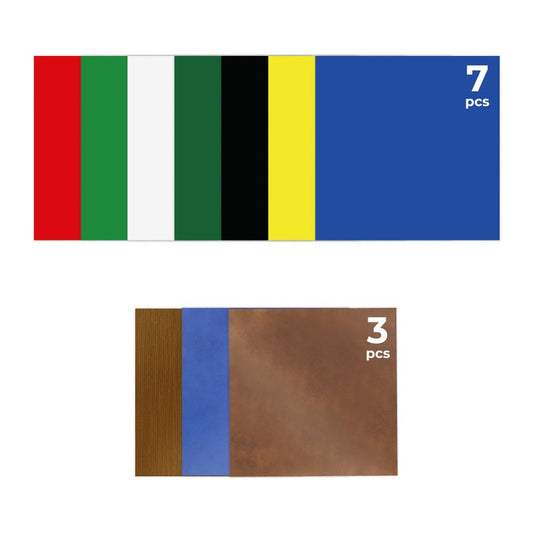

Check this Toocaa Colorful Aluminium Engraving Round Tag.

Brass

Brass can be cut with either CO2 or fiber laser cutters. Fiber laser cutters are preferably used because of their short wavelength, which can melt brass easily. Use them slowly to get a precise, smooth, and accurate cut.

Aluminum

Aluminum is popular among the manufacturing and processing industries. It is easy to cut, so any laser-cutting machine can be used. The cutting or engraving style depends on the thickness of the aluminum and your expected results.

Wood

CO2, diode, and fiber laser cutters can handle soft, hard, and combined woods. For disparity, CO2 lasers are more powerful and efficient with minimal waste production. Diodes are the best option for pictures and any type of artwork because of their diversity of color options.

Check out this Toocaa Multi-shape Wooden Keychain.

Advantages of Laser Cutting System

High Speed

One of the selling points of laser cutting machines is their high speed, which makes cutting very fast. However, this high speed depends on the material's type, laser power, and thickness. This means it is slow when cutting through thick materials above 20 mm and with high heat conduction.

Environmentally Friendly

Laser-cutting machines are eco-friendly if managed well. They have compartments that receive dust and fumes released during the cutting or engraving. The machines are not made with many chemicals that can pollute the air, so they're safe and hazard-free for operators and employees.

Accuracy and Precision

Accuracy and precision are two main features of laser-cutting machines that distinguish them from traditional cutting methods. These features help ease creating, designing, and engraving tasks without sweating.

However, achieving this requires the right settings and mirror alignment to enhance precision and accuracy.

Low Maintenance Cost

The cost of maintaining laser-cutting machines is low if not misused. Clean the debris, tighten every loose bolt and knot, clean the bed, and carry out other basic maintenance regimens. This will increase the lifespan of your machine.

Disadvantages of Laser Cutting System

Despite the mouth-watering benefits of laser-cutting machines, you still want to learn the dark sides of laser cutting machines. Here is what to know:

It Is Expensive

The cost of purchasing a laser cutting machine is expensive. Installation and maintaining the operational costs are more expensive. It's almost three times the price of waterjet cutters or plasma cutters.

However, the price varies depending on the type of laser-cutting machine. Desktop diode laser engraving machines are quite affordable, and they can handle most of the engraving or cutting tasks that laser cutters can perform. You can check out the TOOCAA L2 laser engraving machine, and the accompanying TOOCAA STUDIO software is free.

Although the initial cost of purchase, installation, and maintenance may be high, the return on investment is good. That means you are sure of getting your money's worth quickly.

Limitations to Metal Thickness

Laser-cutting machines can cut materials regardless of their thickness. However, there's a limit to this, especially for inexperienced people. Most machines require an average of 15 to 20 millimeters. Anything above this must be done in the presence of a skilled machinist or under his/her guardianship.

Requires Technical Knowledge

Before handling a laser cutting machine for the first time, you must undergo a series of training sessions.

However, while in training and to ensure the continuity of your business, you may need to employ the services of a machinist or technical personnel. A machinist should be able to operate the machine, understand its settings, and interpret the results. Paying for the services of a machinist may be expensive for small-scale business owners.

Conclusion

It would be ignorant of a business owner or an individual to remain in the obsolete means of cutting and engraving. Technology has gone past that phase.

There are so many laser-cutting machine applications that it is unavoidable not to use them in industries. They include medical, automobile, furniture, aerospace, agricultural, and construction industries.

You will agree that laser-cutting machines are a blessing to the manufacturing industry. If you were unsure whether to purchase one, we hope you are now convinced that a laser cutting machine is a necessary tool to ease your job.

Are you looking for where to shop a quality laser cutting machine, accessories, and materials? Toocaa is the right place to go. You can also contact us with your enquiries about laser cutting machines.