Laser cutting machines are game changers in the production world. From helping industrial production to crafting everyday designs, laser machines make work more seamless.

In line with its obvious efficiency, the machine is compatible with a myriad of materials, which makes it more desirable to use.

However, one burning question on most beginners' minds is whether a laser cutting machine is complex to operate. Given the industrial use of the machine, it's not out of place to think like that.

If you've heard a lot about laser cutting machines but are scared they may be difficult to use, read this to learn how they work and how to use them.

How the Laser Cutting Process Works

A laser cutting machine works through a concentrated laser beam, which transforms energy into heat. The laser generator and laser resonator are responsible for producing a consistent light source, which is then focused into a concentrated beam. The concentrated laser narrows into a straight line and cuts through materials precisely and accurately.

The process of focusing the laser beam is similar to using a magnifying glass to concentrate sunlight to a single point, allowing for intense heat and precise cutting. The mechanical system and cutting head work together to move and focus the concentrated beam along specified paths, enabling accurate and complex cuts.

By moving the laser in different positions, the machine creates different shapes and cuts to form the desired design.

There are three major types of laser cutting machines. They include CO2 laser, fiber laser cutters, and diode laser cutting machines. Fiber laser cutters use fiber optics to deliver a high powered laser beam, utilizing light amplification for efficient and precise metal cutting. The different types of machines may have distinct ways of operating.

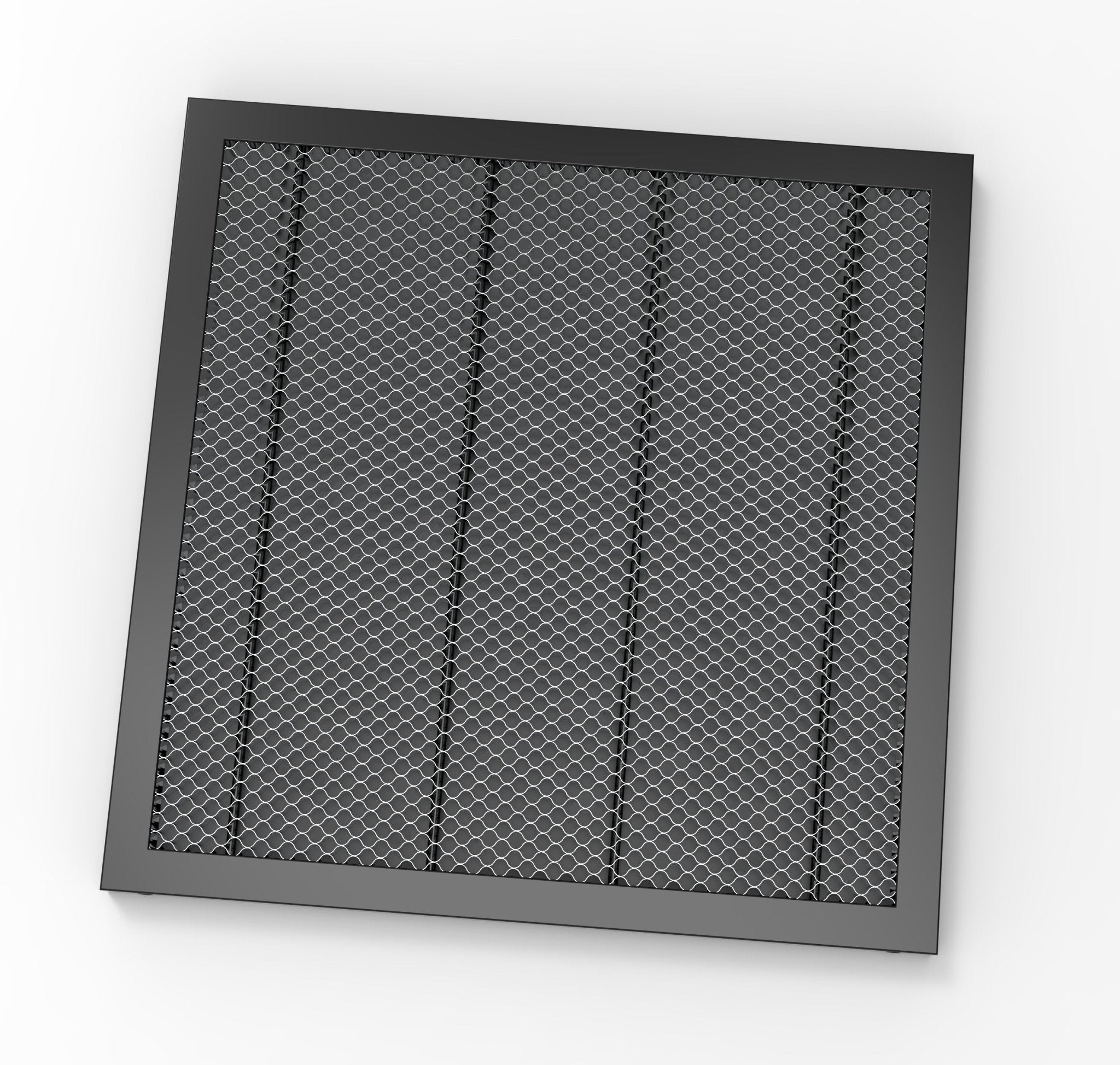

Materials You Need When Laser Cutting

The first step to laser cutting is getting the materials you will need for the process. Here are what you need:

The first step to laser cutting is getting the materials you will need for the process. Laser cutting machines are compatible with different materials, but each workpiece material may require specific settings for optimal results. Here are what you need:

Material to Cut

You can use a laser cutter to cut or engrave materials like acrylic, paper, wood, plastic, or metal. Extruded acrylic and carbon steel are also common examples, but note that carbon steel may have maximum thickness limitations for laser cutting. The choice of cutting material affects the cutting process and results, as different materials require specific laser settings and techniques.

Note: Never attempt to cut materials like PVC or vinyl, as they can release toxic chlorine gas, which is hazardous to both health and equipment.

Note that there are materials you can't cut with a laser cutter, such as PVC and Vinyl. It's advisable to ask the vendor before buying or do your research before going ahead and cutting.

Computer/Design Software

The next important thing when laser cutting is a computer with graphics software, such as TOOCAA Studio or other design software programs, which would help you design and then transmit the same to the laser cutter.

This is, of course, when you're using the laser cutter to design.

Safety Precautions When Using a Laser Cutting Machine

When working with a laser cutting machine, safety should always be your top priority. The high energy laser beam used in the cutting process can pose serious risks, including eye injuries, burns, and respiratory issues from fumes. Always wear appropriate protective gear, such as safety glasses designed for laser work, gloves, and a face mask to shield yourself from harmful particles and light.

Make sure your cutting machine is set up in a well-ventilated area, and use a dedicated ventilation system to remove smoke and fumes generated during laser cutting. Keep your workspace tidy and free from flammable materials, as stray sparks or heat from the laser beam can ignite them. Never leave the machine unattended while it’s running, and always follow the manufacturer’s safety guidelines. Regularly inspect your equipment for any signs of wear or malfunction to ensure safe and reliable operation every time you use your laser cutter.

How to Operate a Laser Cutting Machine

Operating a laser cutting machine may not be as hard as it seems, provided you have all your materials readily available. Understanding how laser cutters work and how the machine work is essential for effective operation, as it helps you grasp the principles behind the focused laser beam, heat conversion, and the mechanics involved. Follow the subsequent steps to operate it effectively:

Step 1: Prepare Your Design

As stated before, you need to have design software on your computer laptop from which you create your design. You may use a plethora of options, including TOOCAA Studio or Lightburn. So, the first step is getting your design ready to be cut.

Step 2: Transfer the Design in an Acceptable Format

Once your design is ready, save it in a design that is compatible with the laser cutting machine, which is usually CNC (Computer Numerical Control) or G code.

The G code is machine language that gives the laser instructions on where to move. You may send the G code or CNC file format to the laser controller via a USB driver or Wi-Fi.

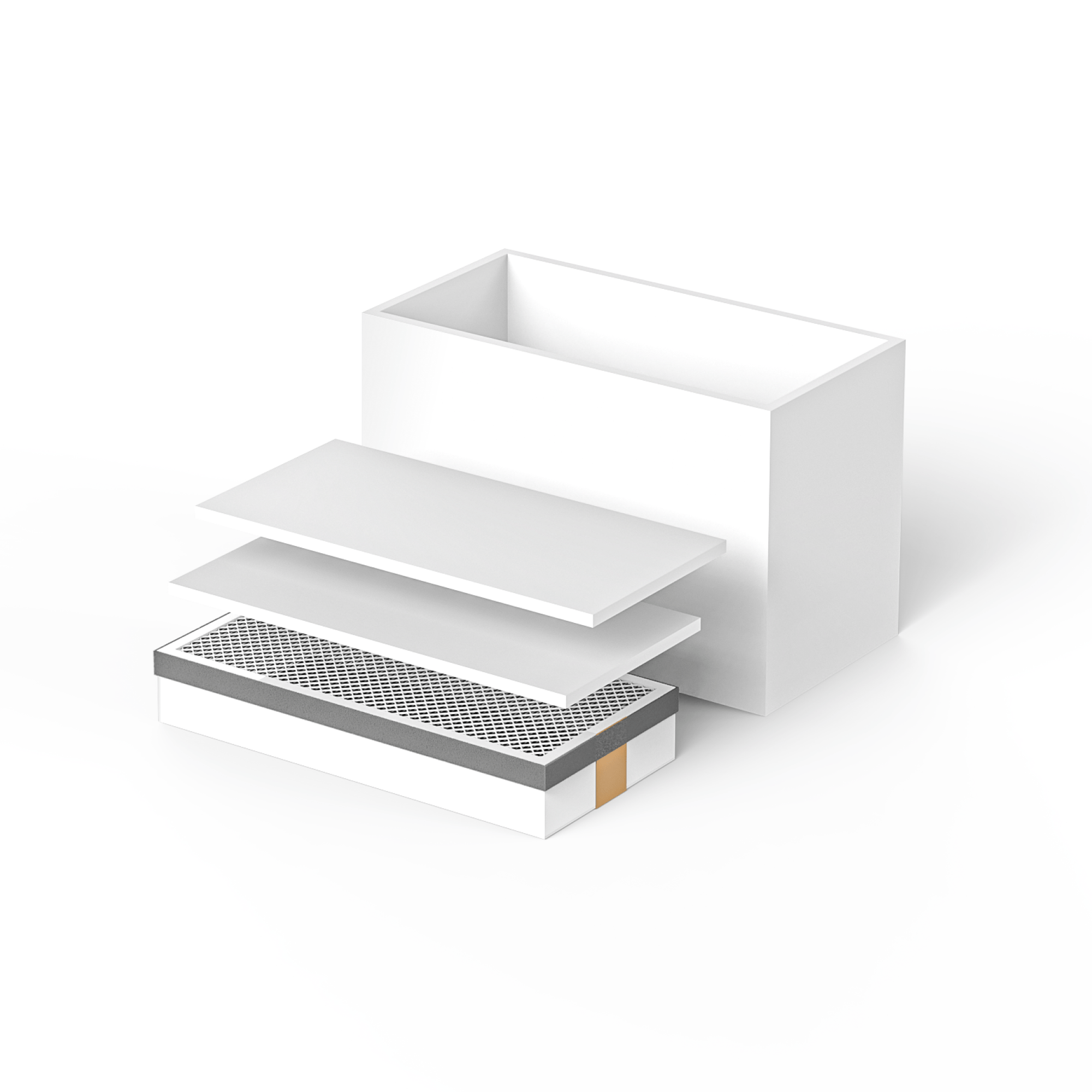

Step 3: Setup the Machine for Cutting

Once you have your material and design, you can set up the machine. Align the laser beam for an accurate cut. The cutting head focuses the laser beam to a precise focal point on the material, which is essential for clean and accurate cuts. The mechanical system moves the cutting head along the specified path, ensuring precise positioning for both cutting and engraving operations.

You can refer back to the manufacturer’s instructions for more insights. Then, open the case and place your material in the laser cutting machine, adjusting its placement based on its type and thickness. Some laser machines come with inbuilt rulers to help you align your materials.

Then, you may need to adjust the bed; do this by pushing the focus button and the down arrow button in the front control panel of the machine. Lowering the bed ensures that your material does not come into direct contact with the laser. Adjusting the bed also helps set the correct focal point, which influences the energy distribution and precision of the cut. Conclude this section by closing the lid.

If you’re still unsure how to proceed, check the manufacturer’s instructions for more information.

Step 4: Set the Power and Speed

The power and speed settings differ according to material, thickness, and machine type. Each material has a maximum thickness that can be cut effectively; exceeding this can negatively affect the cut surface and overall cut quality. Although the manual may provide basic instructions, you will need to research or test your settings to determine which are most appropriate. Proper settings help achieve smooth edges and avoid rough edges, ensuring a professional finish.

However, be careful not to start a fire. Note that the more power you use, the more heat it emits, which makes it more likely to start a fire. For flammable materials such as paper and plastic, use medium to low heat to avoid an escalation.

For the speed, you may also experiment with the settings, but be careful about it. Thicker materials require slower speed than normal, and slower speed makes deeper cuts. High energy density is important for cutting thicker materials efficiently. Also, each laser type has different wattage settings, so it’s almost impossible to generalize your settings. You may test it out and take note of the settings that best work for each material type for future purposes.

When cutting metals, specific laser cutting techniques such as fusion cutting (also known as melt and blow cutting) use an assist gas like nitrogen or argon to blow molten metal or molten material out of the cut, a process called blow cutting. Reactive cutting uses an oxygen jet to react with the heated metal, accelerating the cutting process but potentially affecting the cut surface. Compared to plasma cutting, which is another thermal cutting method for conductive metals, laser cutting generally offers higher precision and better cut quality. The overall laser cutting process and its various techniques require specific settings for optimal results.

Step 5: Frequency Settings

When working with vector, there is an added setting besides power and speed. Vector is a method of laser cutting used to cut things out. Then, there’s raster, which is better at engraving things. Raster cuts more like an inkjet printer, while vector cuts in a straight line, which may cause the design to be faint. Vector cutting can go through the entire thickness of the material, while engraving only marks the surface without cutting all the way through.

The frequency setting refers to the amount of laser pulses per inch applied to the material. Vector, unlike raster, cuts in a straight line instead of printing on the spot, depending on the darkness of the area you’re etching.

So, you have to lower the speed or increase the power to imitate the operation of the normal laser function. The frequency may be set between 10 and 5000 pulses per inch. When working with materials like wood or other flammables, you should use a lower pulse per inch (PPI), as the higher it is, the hotter it gets and may likely burn.

You can test out different settings to figure what you want and the most appropriate settings before going into the main project.

Step 6: Do a Test Run

If you’re operating a laser cutting machine for the first time, it is not advisable to go straight into cutting your project. This is because of mistakes you may make in settings that could ruin your design and material.

Hence, the wise thing to do is to do a test run. Once you have all your settings done based on the instructions above, you could use paper or tape (the blue painter’s tape - easy to remove without stickiness) over the print area to test the machine.

A test run also allows you to observe how the laser interacts with the material's surface, helping you assess if the settings are suitable for the specific surface characteristics before starting the main project.

However, it is most advisable to use a disposable piece of material similar to the one you plan on using to ensure the accuracy of your settings.

If you’re using paper or tape, use high speed and low power, and make sure your exhaust fan is not on. You may test this a couple of times until you’re sure about your settings or ready to cut.

Step 7: Start Cutting or Engraving

Once you’re done testing, remove the tape, paper, or test material and place your correct material. Go to the computer and print as vector or raster, depending on whether you want to cut or engrave. Then, recheck your power and speed settings to ascertain they are the most appropriate for the material you are cutting. If you are cutting brittle materials such as glass or ceramics, special techniques like fracture-controlled cutting or impact cutting may be required to ensure clean results.

Ensure you close your lid and that you have only your material in the working area.

Step 8: Check Out the Finished Product

Once you're done with cutting, check out the finished design and ascertain that it suits your vision. You may wipe off additional excess of the surface where necessary and examine. If it's not precise, try again with another material and adjust the power settings if you notice burning.

Step 9: Clean the Laser Cutting Machine

After your design and cutting process, it's crucial to clean your machine for maintenance purposes. The important materials for need for cleaning include plastic scissor crimps, cotton swab, lens cleaning paper and liquid lens cleaner.

You need to clean the mirrors and lens in the machine. Pick up lens cleaning paper with the scissor crimps or another material you can use to hold the cleaning paper, leave a drop or two of the lens cleaner on it, and clean the lens with it.

Continue by cleaning the mirrors with the cotton swab. Keep changing and cleaning until you have a clean swab after cleaning the mirrors. The mirror, which is far away from the lens, is not frequently cleaned, given that it has no direct impact from the smoke from the laser on the material, but you may clean it when necessary. Also, ensure there is no residue dirt in the laser bed or anywhere else before concluding your cleaning.

Step 10: Redesign, Reset, and Reprint

Do not forget that your settings are totally dependent on the material you're designing on, so if you need to print on another material, you may need to go over these again and ensure you do not create any hazards while cutting.

Also, make sure your laser cutting machine is compatible with the material you intend to cut. It's safe to simply get a laser cutter fit for the purpose you'd usually use it as the wattage of each machine differs and is adjustable based on that.

More importantly, if you're having issues aligning your material on the laser bed, use a ruler that measures the size of the bed to make it easier to design.

Lastly, remember to be safety-cautious by wearing protective wear, ensuring that the area is well-ventilated, and not cutting any material impregnated with resin or other oils.

Operator Training: Getting Started with Laser Cutting

Before diving into your first project, it’s important to get proper training on how to use a laser cutting machine. Operator training covers the essentials of laser cutting, from understanding how laser generation works to mastering different cutting techniques. You’ll learn how to set up your machine, adjust the laser beam, and select the right parameters for various materials.

Hands-on practice is key—spending time with the machine helps you build confidence and develop the skills needed for precise and safe operation. Many manufacturers and suppliers offer training sessions, workshops, and online tutorials to help you get started. By investing in comprehensive training, you’ll be better equipped to handle the machine, troubleshoot issues, and achieve the best results with your laser cutting projects.

Troubleshooting Common Laser Cutting Issues

Even with careful setup and maintenance, laser cutting machines can sometimes run into problems that affect the quality of your cuts. If you notice poor cut quality, rough or uneven edges, or the machine isn’t performing as expected, start by checking your laser power and cutting speed settings. Incorrect parameters can lead to incomplete cuts or excessive burning.

Next, inspect the focusing lens, mirrors, and beam delivery system for dirt, damage, or misalignment, as these can impact the precision of the laser beam. Make sure the material you’re using is suitable for laser cutting and that your chosen cutting technique matches the material’s thickness and type. If issues persist, consult your machine’s manual, reach out to the manufacturer’s support team, or seek advice from experienced laser cutting operators. Addressing these common issues promptly will help you maintain high cut quality and keep your projects on track.

Maintenance and Repair of Laser Cutting Machines

Keeping your laser cutting machine in top condition is essential for consistent performance and long-term reliability. Regular maintenance includes cleaning the lens, mirrors, and beam delivery system to prevent buildup that can affect the laser’s accuracy. Check for worn or damaged parts and replace them as needed to avoid unexpected breakdowns.

It’s also important to monitor the machine’s power supply, cooling system, and ventilation to prevent overheating and ensure safe operation. Update your machine’s software regularly to benefit from the latest features and improvements. If you encounter any malfunctions or damage, contact the manufacturer’s support team or a qualified technician for repairs. By following a routine maintenance schedule, you’ll extend the life of your laser cutting machine and enjoy smooth, trouble-free operation.

Applications of Laser Cutting

Laser cutting technology is incredibly versatile, making it a valuable tool across a wide range of industries. In manufacturing, construction, automotive, aerospace, and healthcare, laser cutting is used to shape metals, plastics, wood, and textiles with extreme accuracy. The ability to cut thin materials and brittle materials like glass and ceramics sets laser cutters apart from traditional cutting methods.

Beyond industrial uses, laser cutting is popular for engraving, marking, and creating intricate designs in fields such as architecture, art, and product design. Whether you’re working with thin sheets of metal or delicate plastic materials, laser cutting offers precise, clean cuts and the flexibility to handle complex shapes. As laser cutting technology continues to advance, its applications are expanding, making it an essential tool for modern manufacturing and creative projects alike.

Conclusion

Is the operation of a laser cutting machine complex? Not totally, not if you follow the instructions in this piece squarely.

Operating a laser cutting machine is not easy, but it is doable with the right tutorial. Each machine has its specifications, so it's important to note the differences in how each works. However, these steps are basic ones and should guide you along properly.

Also, ensure you get your machines and materials from reliable stores and ask about necessary features and user guides before bringing them home. If you're still not confident about operating your laser cutting machine yourself, then you should contact a professional to help in your design or production.

Are you looking for where to shop your laser cutting machine, materials, and accessories? TOOCAA is the right store to find solutions to your laser.

Contact us today.