Laser engraving is an advanced technology widely used in various industries. For marking and personalization, It uses a laser beam to create permanent, highly accurate patterns on a wide variety of materials. This article details the basics of laser engraving, its uses, and benefits.

BASICS OF LASER ENGRAVING

DEFINITION

Laser engraving is a subtractive manufacturing process that uses a powerful laser beam to remove material from the surface of an object. This process creates a permanent, highly detailed design, message, or pattern.

COMPOUND

The laser engraving process consists of three main steps.

1. Create your design Create your digital design using graphic design software. This design will be loaded into the software to control the laser engraving machine.

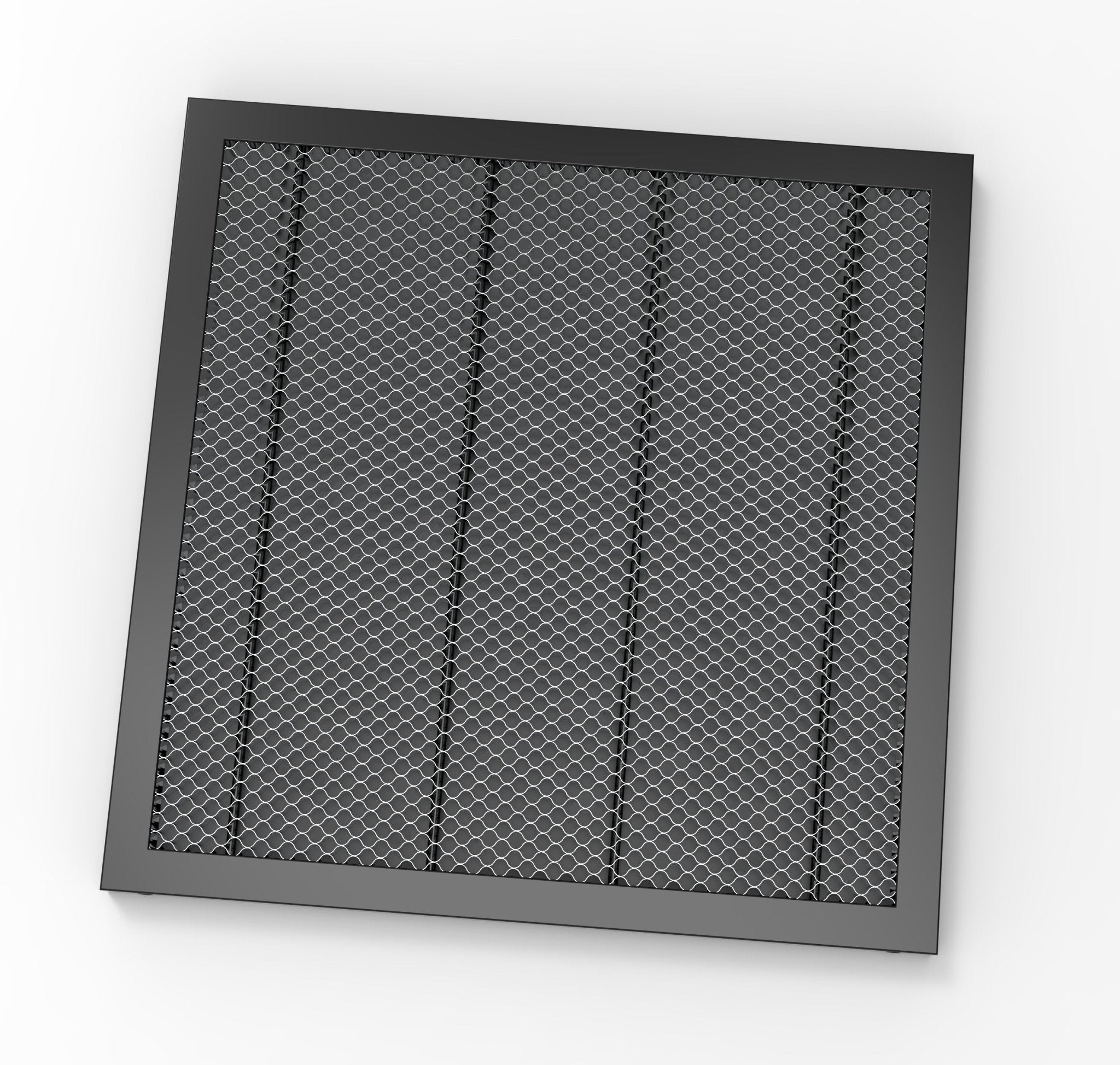

2. Material preparation: Place the engraving material on the laser engraving machine table and fix it.

3. Engraving: The laser beam is directed towards the material along a path determined by the digital design. The intensity and speed of the laser can be adjusted to achieve the desired depth and detail.

TYPE OF LASER USED

Many types of lasers are used for engraving. Each type is tailored to specific materials and applications.

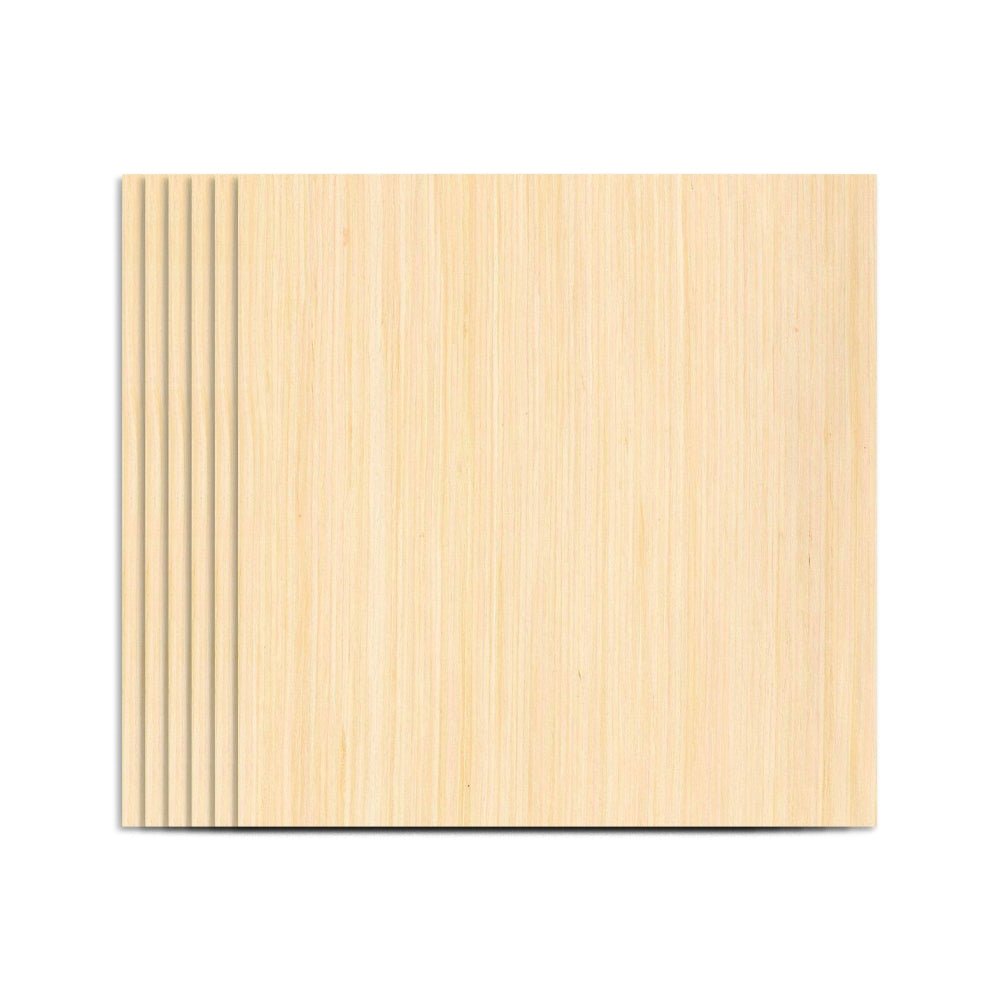

CO2 laser: Often used to process non-metallic materials such as wood, glass, acrylic, leather, and some plastics.

Fiber laser: suitable for some metals and plastics. Provides high accuracy and high speed.

Diode laser: Generally used for small projects and low-intensity applications.

APPLICATIONS OF LASER ENGRAVING

INDUSTRIAL USE

Product Identification: Laser engraving is used to mark products with serial numbers, barcodes, and QR codes for identification and tracking purposes.

Tool Marking: Engraving tools and equipment facilitate asset management and prevent loss or theft.

COMMERCIAL AND ARTISTIC USE

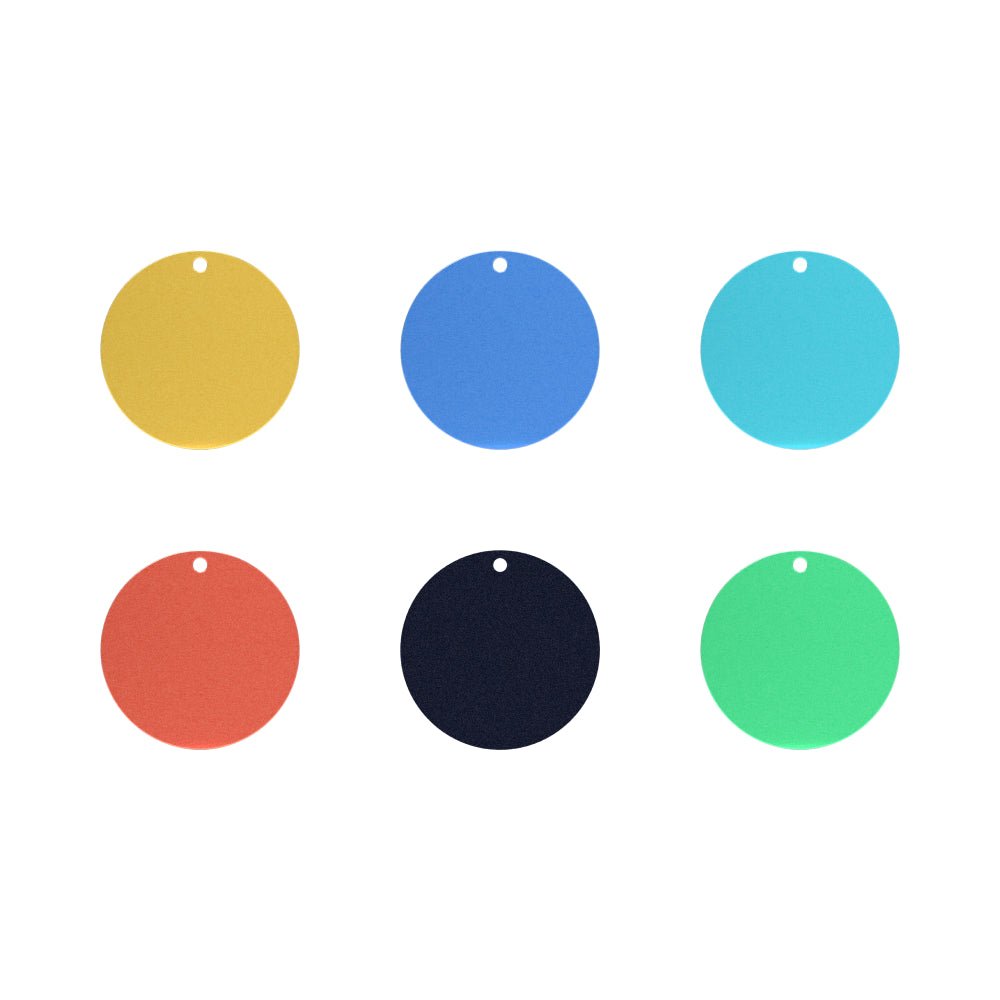

Personalization: Personalized items such as jewelry, awards, and gifts are often laser engraved with names, dates, and unique designs.

Arts and Crafts: Artists and designers use laser engraving to create intricate patterns and designs on a variety of materials.

MEDICAL USE

Medical devices: Laser engraving is used to mark important information on medical devices and instruments. To ensure traceability and compliance with regulations

ELECTRONICS

Marking of components Electronic components and printed circuit boards are often laser etched for identification and marking.

BENEFITS OF LASER ENGRAVING

PRECISION AND DETAIL

Laser engraving provides unmatched precision. and allows you to create intricate and detailed designs that are difficult to achieve using traditional methods.

SUSTAINABILITY

Laser-created engravings are durable. It can be used for a long time even in harsh environments

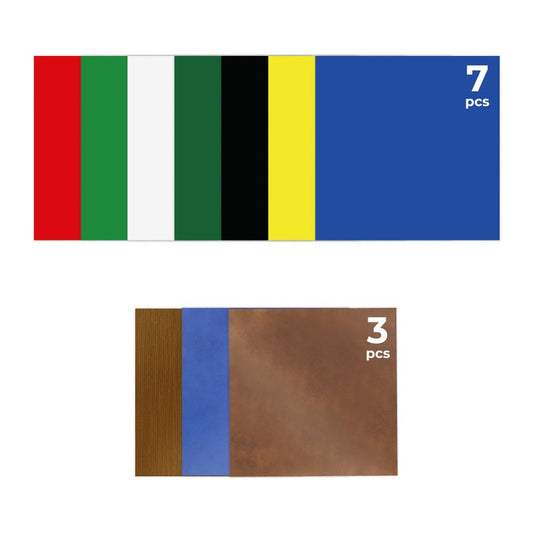

VERSATILITY

Laser engraving can be used on a wide variety of materials, including metal, plastic, wood, glass, and ceramic. This versatility makes it suitable for a wide range of industries and applications.

SPEED AND PERFORMANCE

Laser engraving is a quick process. Especially when compared to traditional carving methods. This efficiency increases business productivity and reduces response times.

CONTACTLESS PROCESS

Laser engraving is a non-contact process. Therefore, the risk of damage to the carved material is very small. This is especially important for delicate and delicate items.

ECOLOGY

Laser engraving does not use chemicals or hazardous materials. This makes it environmentally friendly. In addition, the precision of the process reduces waste to a minimum.

CONCLUSION

Laser engraving is a powerful technology that combines precision, versatility, and efficiency. Applications cover a wide range of industries. From industrial production to art, It emphasizes the importance of this in modern society, by understanding the basics and benefits of laser engraving. Businesses and individuals can use this technology to improve their products and achieve high-quality results in the long term.

I'm very happy to recommend this video to you. In this video, Alexander Sellite of "Laser Everything" breaks down everything we need to know about fiber lasers and how they function. I hope it can help you better understand how do laser beams engrave things.