It’s a practical, evidence-based manual for avoiding fires, minimizing damage if something does ignite, and building repeatable safety habits that actually get used—not just framed on the shop wall.

Why laser engravers catch fire (and why vigilance beats gizmos)

Lasers don’t “set things on fire” by magic; they concentrate heat to the point where a material pyrolyzes (breaks down) and releases combustible gases. If those gases meet enough oxygen and a hot spot, you get flame. Add chips, soot, or resinous offcuts that smolder, and you have a recipe for escalation.

Real-world fire reports from the maker community show the same pattern: unattended jobs, resin-rich woods or cardboard, accumulated debris on the honeycomb bed, and insufficient air movement. Community threads emphasize that human supervision outperforms most “automatic” solutions because many suppression devices trigger after a flame has already developed—by then you may already have damage.

Institutional safety programs push the same core point in drier language: operate with appropriate ventilation/filtration, use approved materials, maintain the machine, and never run the cutter unattended.

gadgets are assistants, not babysitters. A present, trained operator is the fire-prevention tool.

The four pillars of fire safety for desktop lasers

Pillar 1 — Engineering controls (the hardware and environment)

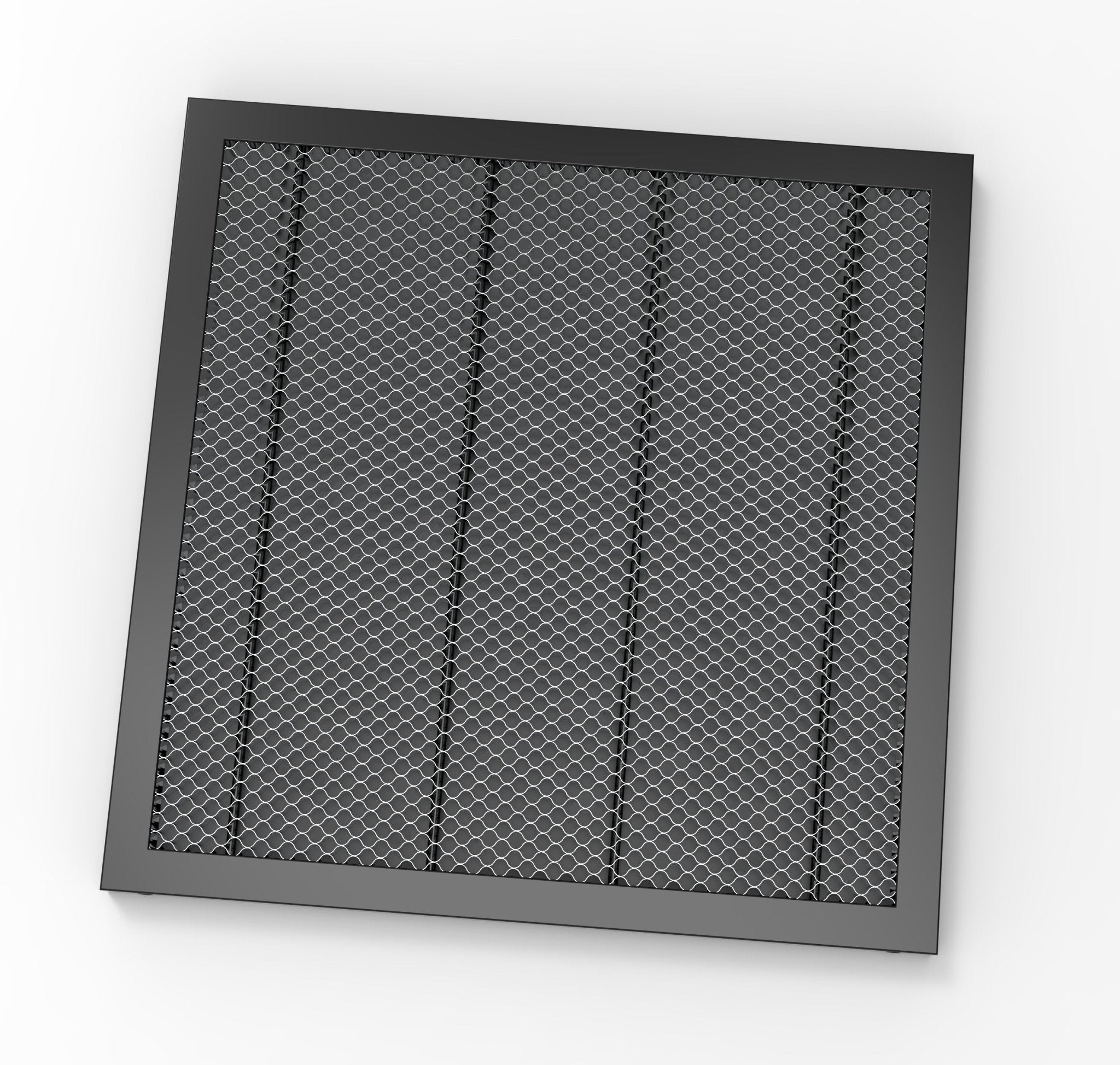

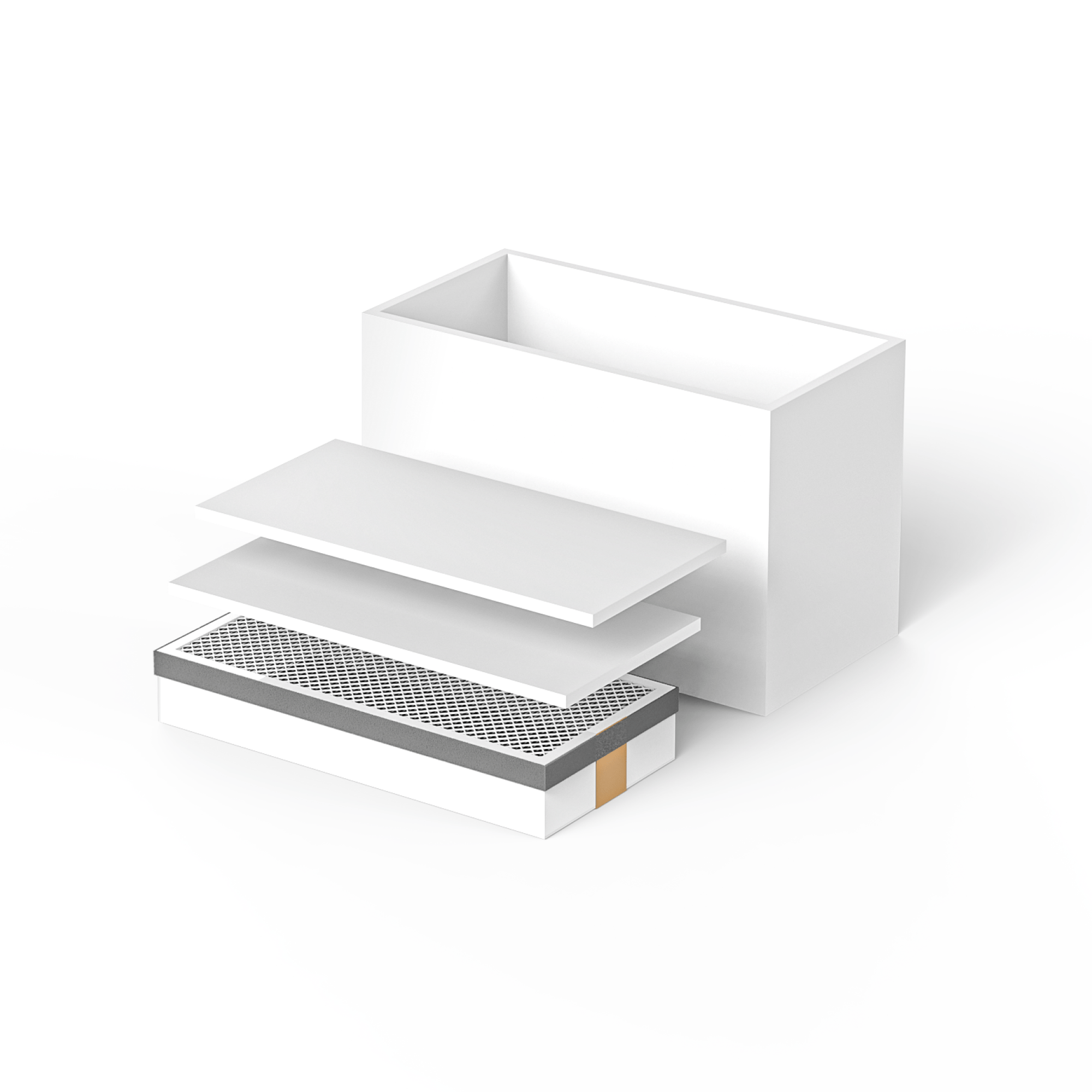

Enclosure & interlocks : An enclosure reduces stray beam risk and helps contain early flame/sparks; with many systems, enclosure + interlocks elevate overall safety.

Ventilation and filtration:Provide adequate exhaust airflow and static pressure per manufacturer guidance, and keep filters on a replacement schedule; degraded airflow increases flame risk by allowing heat and fumes to pool.

If a filter or exhaust behaves abnormally, stop operation immediately and troubleshoot before resuming.

Air Assist: Proper air assist helps blow away hot fragments, cool the kerf, and suppress flare-ups. Pair the nozzle and flow with your material: just enough to clear the cut and reduce charring without scattering embers.

Workspace layout : Keep the engraver on a non-combustible surface, clear the area of paper, solvents, and sawdust, and maintain good lighting/visibility. Regularly vacuum the honeycomb bed and internal cavity; debris is tinder.

Detection and cameras (as supplements): A camera plus a visible work window helps you watch the cut without hovering. Consider a smoke detector in the room (placed to avoid nuisance trips from normal fume paths). Treat detection as early warning, not permission to leave.

Pillar 2 — Administrative controls (the rules and the routine)

Approved materials list & SDS

Maintain a “white list” of materials you’ve verified as compatible (plywood grades, solid woods, acrylic/PMMA, anodized aluminum marking, etc.) and a “blacklist” of no-go materials like PVC or other chlorine-containing plastics that release hydrochloric acid and chlorine when heated—highly corrosive to optics and hazardous to you. Always consult the Safety Data Sheet (SDS), especially Section 10 (Stability and Reactivity), for decomposition products.

Training & SOP

Build a short, concrete operating procedure that operators actually follow: pre-run checks, during-run supervision, post-run cleanup and logging. UW and MIT provide model checklists and focus sheets that you can adapt to the home or studio context.

Build a short, concrete operating procedure that operators actually follow: pre-run checks, during-run supervision, post-run cleanup and logging. UW and MIT provide model checklists and focus sheets that you can adapt to the home or studio context.

No-leave policy

If the laser is running, a trained operator is present. Period. The most convincing case studies come from people who stepped away “only for a minute.”

Job planning

Prefer multiple lighter passes over a single slow pass when cutting tricky organics; this reduces heat soak and flare-ups. Combine this with conservative power/speed test cards per material, saved as TOOCAA Studio or LightBurn templates.

Pillar 3 — Maintenance (the boredom that saves machines)

Clean optics (lens, mirror, protective shields) and the air path; resin fog and soot increase localized heating.

Vacuum chips/ash from the bed and under the honeycomb after each session.

Replace filters on schedule to keep airflow in spec.

These items are all called out in institutional checklists as primary fire-prevention measures.

Pillar 4 — Emergency readiness (when prevention misses)

Keep a CO₂ (Class B) or clean-agent extinguisher within arm’s reach; know the PASS steps (Pull, Aim, Squeeze, Sweep). Many EHS programs explicitly recommend CO₂ for laser cutters because it leaves no residue that could damage optics and electronics.

Kill power to the machine before discharging an extinguisher. If the fire is larger than a small waste-basket, evacuate and call emergency services.

Materials: what’s safe, what’s risky, and how to tell

The no-go list (hard stop)

PVC (polyvinyl chloride) and other chlorinated plastics (like some vinyls) generate HCl and chlorine; these are corrosive to optics and electronics and hazardous to breathe. Don’t cut or engrave them.

Unknown foam cores and composites (e.g., sign materials with polyethylene or PVC cores) can surprise you—community incident reports show they can ignite rapidly.

Conditional/handle-with-care

MDF and resin-rich plywoods: prone to smoldering; use multiple passes, strong air assist, and close supervision. Community threads frequently report flare-ups with MDF.

Cardboard & paperboard: ignite easily; keep passes light and fast; remove lingering embers.

Reflective metals: generally you mark, not cut, with a diode engraver. If you must process shiny surfaces, dull them with a marking spray to avoid stray reflections and hot spots (and, for high-power CO₂/fiber systems, follow manufacturer guidance).

Extinguishers, blankets, and what to do when you see flame

Choosing and positioning extinguishers

Keep a CO₂ extinguisher near your engraver. It’s effective on small Class B fires (flammable liquids/gases) and leaves no residue—safer for optics than ABC powders. EHS sheets commonly recommend CO₂ for laser cutter stations.

A fire blanket is useful for snuffing small surface flames without blasting chips or powder into the optics bay.

The micro-SOP for incidents

Pause/stop the job and cut power to the machine.

If the flame is small and localized, discharge CO₂ at the base or use a blanket.

If it grows beyond a small waste-basket or you are uncertain: evacuate and call emergency services.

After any incident, document what happened, inspect optics/wiring/bed, and service the exhaust/filters.

Software habits in LightBurn & TOOCAA Studio that reduce risk

Project preparation

Use layers to separate engraving and cutting; run engraving first so your cut perimeter doesn’t free the part prematurely (a lifted part can catch).

Create and reuse material libraries with conservative defaults; record any tendency toward edge glow and the Air Assist flow that fixed it.

For cutouts with tiny bridges, add tabs so small pieces don’t tilt up and meet the beam.

Path strategies

Prefer inside-out cutting so internal features are cut before outer profiles—this keeps the workpiece stable.

For resinous woods or cardboard, choose higher speed / lower power with two or more passes, watching for soot.

Simulate toolpaths and time estimates; plan to be present the entire time.

Frequently asked questions

Can I laser-cut PVC if I have good exhaust?

No. PVC releases HCl and chlorine under laser heat; these are corrosive and hazardous. You’ll attack mirrors, lenses, and metal, and risk your lungs. Choose alternative plastics like PMMA (acrylic) for clear parts.

How does TOOCAA Studio help reduce fire risks compared to generic workflows?

TOOCAA Studio helps reduce fire risks by offering material-specific safety presets that adjust cutting power and speed for safer operation. It also provides real-time monitoring to alert users of unsafe parameters, and optimizes cutting paths to reduce heat build-up, ensuring a safer, more controlled cutting experience.

Does the TOOCAA L2 have built-in fire safety features?

Yes, the TOOCAA L2 Desktop Laser Engraver & Cutter includes built-in fire safety features such as Air Assist to reduce flare-ups by cooling the material and clearing debris, and enclosure compatibility to help contain sparks and heat. Additionally, it has overheating protection that automatically shuts down the system if components exceed safe temperatures.

Is a flame sensor enough to run unattended?

No. Sensors can help, but human supervision is still required. Community incident logs and institutional guidance both stress do not leave the machine while operating.

Do I need an enclosure on a desktop diode machine?

An enclosure with interlocks improves safety and fume control and, for some systems, changes the overall classification to Class 1 during normal operation. It also improves visibility and airflow management.

Conclusion — Safe engraving with TOOCAA L2

Fire safety with laser engravers is not about fear, it’s about building habits that let creativity flourish without risk. With the right combination of engineering controls, safe materials, disciplined routines, and emergency readiness, you can engrave and cut with confidence.

The TOOCAA L2 Desktop Laser Engraver & Cutter, together with TOOCAA Studio and LightBurn workflows, is designed to make those best practices easier: from reliable Air Assist and optional enclosure systems, to software templates that encourage safe parameters.

At TOOCAA, we believe precision and safety go hand in hand. By following the guidance in this manual and making it part of your daily workflow, your L2 machine will deliver years of productive, worry-free service.